Removal and replacement procedures 41

To remove the bezel blank:

1.

Turn off the server and all the peripherals connected to it.

2.

Unplug all external cables and AC power cords. If necessary, label each one to expedite

reassembly.

3.

Remove the unit from the rack and place on a flat surface.

4.

Remove the top cover.

5.

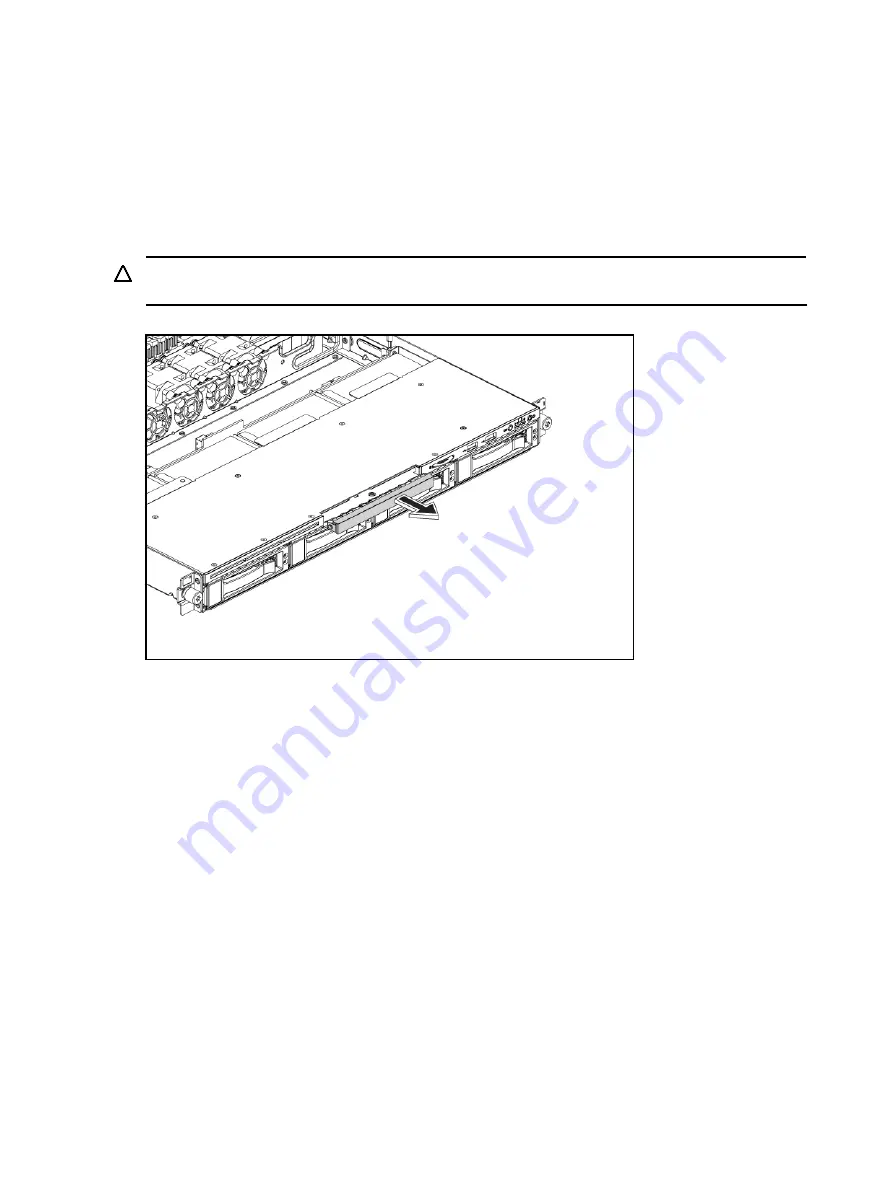

Pull the bezel blank out of the carrier.

CAUTION:

Do not discard the bezel blank. If the optical drive is removed in the future, you must

reinstall the bezel blank to maintain proper system function.

Figure 9

Removing the Bezel Blank

To install the optical drive:

1.

Slide the optical drive assembly into the chassis.

2.

Remove the top cover, fasten the screws and connect the IDE data and power cables to their

corresponding connectors on the optical drive.

Содержание ProLiant DL160se - G6 Server

Страница 12: ...Customer self repair 12 ...

Страница 13: ...Customer self repair 13 ...

Страница 14: ...Customer self repair 14 ...

Страница 15: ...Customer self repair 15 ...

Страница 20: ...Illustrated parts catalog 20 ...

Страница 55: ...Removal and replacement procedures 55 Figure 31 Reinstalling the Backplane 3 Install all cables ...