ENWW

Testing the substrate transport system 171

21

Repeat steps 6 through 8. Verify that the paper feeds past the flat spring of the front

static guide, make sure that there is a gap of 2 mm (0.078 inch) between the paper

and the tip of the spring.

22

If the paper is touching the spring, the paper stock in the Paper Feed Unit must be

moved to the rear of the press. If the paper gap is more than 2 mm (0.078 inch), then

the input tray must be moved to the front. Make sure the front springs touch the paper

stock in the Paper Feed Unit.

Note

If necessary, bend the flat spring on the front static guide to obtain a gap of 2 mm (0.078 inch)

between the paper and the front static guide.

23

Lower the secondary conveyor.

24

Make sure that the paper in tray B (the upper paper stack) is the same size as that

used in tray A (the lower paper stack). Other paper parameters (such as glossy) are

unimportant.

25

Push the tray B

Paper Feed

button, and the

Inching Forward

button to advance the

creased paper.

26

When the creased paper is under the feed rollers of the Paper Feed Unit, push the

Paper Feed

button again to stop the vacuum.

27

From the exit side of the Paper Feed Unit, press the

Inching Forward

button until the

creased paper arrives at the front static guide flat spring.

28

Make sure that there is a gap of 2 mm (0.078 inch) between the paper and the tip of

the spring.

29

Adjust the stack in tray B, as necessary.

Testing the substrate transport system

Test the loaded substrate every time you replace the substrate. Fine-tune the press

adjustment in this mode before printing. Check the performance of the feed control, paper

transport rotors, and the exit stack paper setting.

1

On the control panel, click the

Maintenance

menu, and then select

Transport

. The

Substrate transport

window opens.

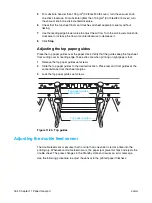

Figure 11-32. Gap between flat spring and paper

2 mm (0.078 inch) gap

Paper

Front static

guide

Paper feed

direction

Содержание Indigo press 3050

Страница 1: ...HP Indigo press 3050 User guide English version ...

Страница 2: ...hp indigo press 3050 user guide ...

Страница 13: ...12 Chapter 1 Preface ENWW ...

Страница 23: ...22 Chapter 2 Getting started ENWW ...

Страница 41: ...40 Chapter 4 HP Indigo press 3050 basics ENWW Figure 4 5 Related topics ...

Страница 53: ...52 Chapter 5 The main windows ENWW ...

Страница 83: ...82 Chapter 6 Operating the press ENWW ...

Страница 91: ...90 Chapter 7 Operator routines ENWW Figure 7 7 Inner front wall O O O O ...

Страница 99: ...98 Chapter 7 Operator routines ENWW ...

Страница 131: ...130 Chapter 9 Blanket ENWW 6 Click Next Figure 9 22 First transfer Wizard define the correct pressure here Rear Front ...

Страница 136: ...ENWW 135 10PIP This chapter contains the following sections z Overview z Replacing the PIP ...

Страница 189: ...188 Chapter 11 Paper transport ENWW ...

Страница 190: ...ENWW 189 12Impression drum This chapter contains the following sections z Overview z Replacing the impression paper ...

Страница 212: ...ENWW 211 15Scorotron This chapter contains the following sections z Overview z Scorotron maintenance procedures ...

Страница 219: ...218 Chapter 15 Scorotron ENWW ...

Страница 254: ...ENWW 253 17Pre transfer erase PTE This chapter contains the following sections z Overview z Cleaning the PTE cover ...

Страница 257: ...256 Chapter 17 Pre transfer erase PTE ENWW ...

Страница 271: ...270 Chapter 19 Chiller ENWW ...

Страница 272: ...ENWW 271 20Long term shutdown This chapter contains the following section z Long term shutdown ...

Страница 287: ...286 Appendix B Service and support ENWW ...