100 Chapter 8 Handling ink

ENWW

Overview

HP ElectroInk, the ink used on the press, is mixed on the press from three components:

imaging oil, imaging agent, and ink concentrate. Ensure a constant supply of both the

imaging oil and the ink concentrate. The press system automatically identifies shortages

of either of the two components, and prompts you to take the correct course of action.

To ensure consistent printing quality and smooth press operation, the press monitors the

following ink characteristics:

z

density (concentration of pigment particles in the ink)

z

conductivity (the adherence capacity of ink to the image areas and its repulsion from

non-image areas)

z

temperature (determines adherence of ink capacity to the substrate)

z

ink tank levels

When the ink characteristics approach the specification limit, the press system displays a

warning message. If you ignore the warning, and the ink characteristics slip outside the

limits, the press changes to the Standby

state.

The press ink system is a semi-closed system. The press system creates ink in the ink

tank using imaging oil and ink concentrate supplied automatically by the press system. Ink

is charged by an automatic addition of imaging agent and is heated to 30° C (86° F). The

pump stirs the mixture and drives it through the pipes. The press system pumps each ink

to its respective BID where it adheres to the PIP.

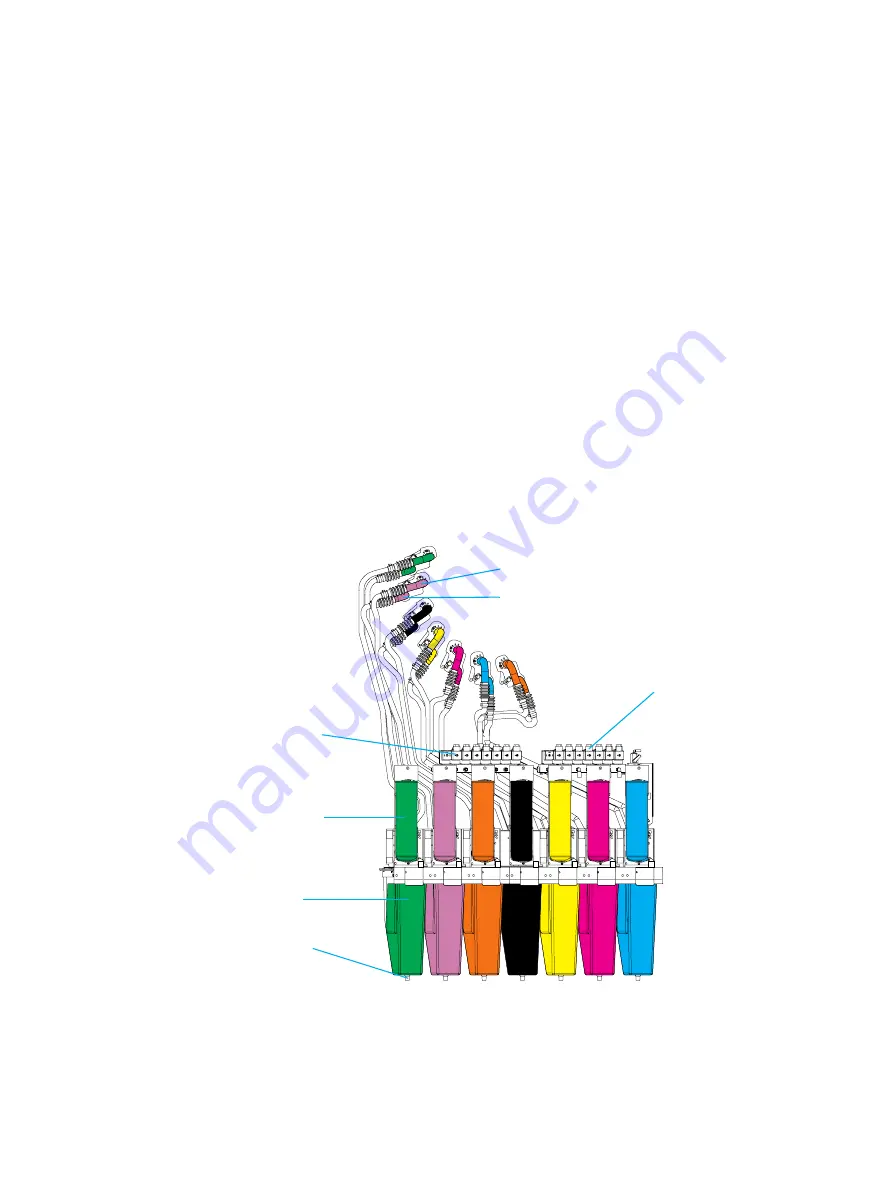

Figure 8-1. Ink system

Ink

tanks

Ink can

positions

Drain

outlet

BID inlet

Air

pressure

valves

Imaging oil

and imaging

agent valves

BID outlet

Содержание Indigo press 3050

Страница 1: ...HP Indigo press 3050 User guide English version ...

Страница 2: ...hp indigo press 3050 user guide ...

Страница 13: ...12 Chapter 1 Preface ENWW ...

Страница 23: ...22 Chapter 2 Getting started ENWW ...

Страница 41: ...40 Chapter 4 HP Indigo press 3050 basics ENWW Figure 4 5 Related topics ...

Страница 53: ...52 Chapter 5 The main windows ENWW ...

Страница 83: ...82 Chapter 6 Operating the press ENWW ...

Страница 91: ...90 Chapter 7 Operator routines ENWW Figure 7 7 Inner front wall O O O O ...

Страница 99: ...98 Chapter 7 Operator routines ENWW ...

Страница 131: ...130 Chapter 9 Blanket ENWW 6 Click Next Figure 9 22 First transfer Wizard define the correct pressure here Rear Front ...

Страница 136: ...ENWW 135 10PIP This chapter contains the following sections z Overview z Replacing the PIP ...

Страница 189: ...188 Chapter 11 Paper transport ENWW ...

Страница 190: ...ENWW 189 12Impression drum This chapter contains the following sections z Overview z Replacing the impression paper ...

Страница 212: ...ENWW 211 15Scorotron This chapter contains the following sections z Overview z Scorotron maintenance procedures ...

Страница 219: ...218 Chapter 15 Scorotron ENWW ...

Страница 254: ...ENWW 253 17Pre transfer erase PTE This chapter contains the following sections z Overview z Cleaning the PTE cover ...

Страница 257: ...256 Chapter 17 Pre transfer erase PTE ENWW ...

Страница 271: ...270 Chapter 19 Chiller ENWW ...

Страница 272: ...ENWW 271 20Long term shutdown This chapter contains the following section z Long term shutdown ...

Страница 287: ...286 Appendix B Service and support ENWW ...