39

8.3

RE-ASSEMBLY 163 COMPRESSOR AFTER OVERHAUL (Continued)

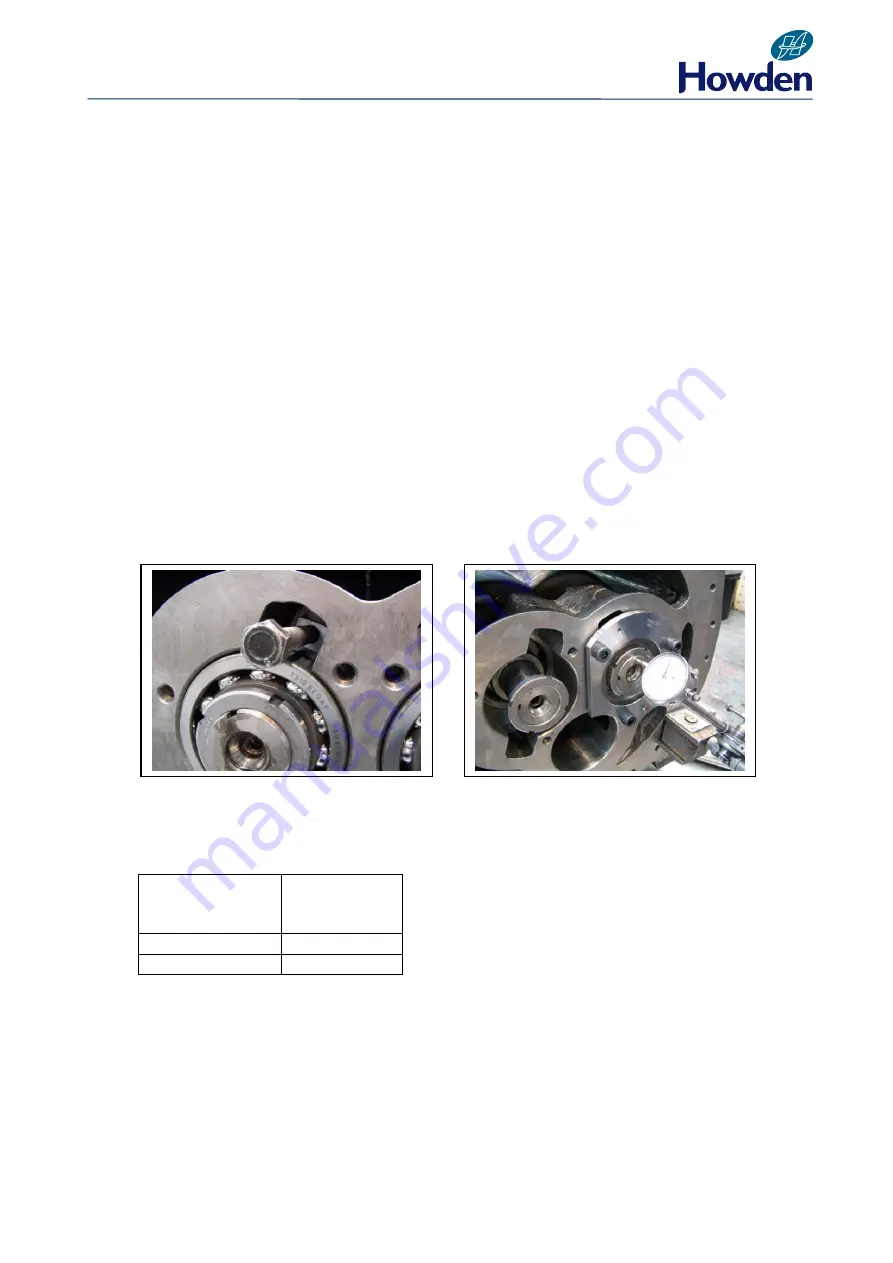

Checking Rotor to main casing Outlet End Clearance (163mm)

1.

Remove the thrust retaining plate (if fitted).

2.

The adjusting plate behind the thrust bearings has two lugs with tapped holes for withdrawal

purposes.

3.

Insert jacking screws into the lugs and lightly tension the screws until resistance if felt (Fig.

49).

4.

The action of tightening the screws draws the rotors hard against the outlet end of the main

casing.

5.

Remove the jacking screws.

6.

Replace the thrust retaining plate and the retaining screws (Figs. 33-34).

7.

Fit a clock gauge in a suitable point on the casing with the spindle of the gauge touching the

end of the rotor (Fig 50).

8.

Set the clock dial to zero.

9.

Torque up the plate retaining screws using a torque wrench to 14Nm.

10.

Note the movement on the clock gauge. This is the rotor outlet end clearance and should

correspond to the table as per Fig. 51.

11.

Adjustment, if necessary, is carried out by machining of the thrust bearing withdrawal plates.

Fig. 49

Fig. 50

Rotor Outlet End

Clearance

163 Compressor

Maximum

Allowable

Clearance

0.050/0.075mm

0.100mm

0.002/0.003”

0.004”

Fig. 51 WRV 163 Outlet End Clearance

Содержание WRV

Страница 1: ...WRV WRVi COMPRESSOR RANGE SERVICE MANUAL...

Страница 3: ...2 SECTION 1 FOREWORD...

Страница 5: ...4 HOWDEN SECTION 2 DESCRIPTION...

Страница 10: ...9 SECTION 3 INSTALLATION...

Страница 14: ...13 SECTION 4 FIRST START UP...

Страница 16: ...15 SECTION 5 NORMAL OPERATION...

Страница 18: ...17 SECTION 6 PROCEDURES DURING SHUTDOWN...

Страница 20: ...19 SECTION 7 MAINTENANCE...

Страница 33: ...32 SECTION 8 OVERHAUL...

Страница 50: ...49 SECTION 9 SPECIAL INSTRUCTIONS...

Страница 57: ...56 SECTION 10 SPARES...

Страница 64: ...63 Printed in the UK Issue HCL September 2012 Howden Compressors Limited...