Controllers

134

customer.honeywell.com

70-6925

condition against the nozzle pressure. If the setpoint is

changed, the forces in the lever system are unbalanced and the

room ambient temperature must change in a direction to cause

the bimetal to rebalance the lever system.

Fig. 17. Relationship between Setpoint, Branchline

Pressure, and Throttling Range.

For example, if the setpoint of a direct acting thermostat is

increased, the bimetal reduces the force applied to the flapper

and raises the flapper off the nozzle. This movement causes

the branchline pressure to bleed down and a heating valve to

open. Heat enters the space until the temperature at the

thermostat increases and the force of the bimetal is again in

equilibrium with the opposing force of the pressure at the

nozzle. Decreasing the setpoint causes the reverse to occur.

The throttling range adjustment provides the means for

changing the effective length of the cantilever bimetal in the

lever system. When the throttling range adjustment is

positioned directly over the nozzle, the force of the bimetal

increases and a narrow throttling range or very high sensitivity

results. For example, a change in temperature of 1 degree F

could result in a branchline pressure change of 5 psi.

When the throttling range adjustment is moved toward the end

of the bimetal and away from the nozzle, the force of the

bimetal is reduced. This reduction requires a greater

temperature change at the bimetal to throttle the flapper over

the nozzle. The result is a wider throttling range or very low

sensitivity. For example, a temperature change of 1 degree F

could result in a branchline pressure change of only 1 psi.

CONTROLLERS

General

A controller is the same as a thermostat except that it may have

a remote sensing element. A controller typically measures and

controls temperature, humidity, airflow, or pressure. Controllers

can be reverse or direct acting, proportional or two-position,

single or two pressure, and bleed, feed and bleed, or pilot

bleed.

A two-position controller changes branchline pressure rapidly

from minimum to maximum (or from maximum to minimum) in

response to changes in the measured condition, thus providing

ON/OFF operation of the controlled device.

A proportional controller changes branchline pressure

incrementally in response to a change in the measured

condition, thus providing modulating operation of the controlled

device.

A proportional-integral (PI) controller adds to the proportional

controller a component that takes offset into account. The

integral component eliminates the control point offset from the

setpoint.

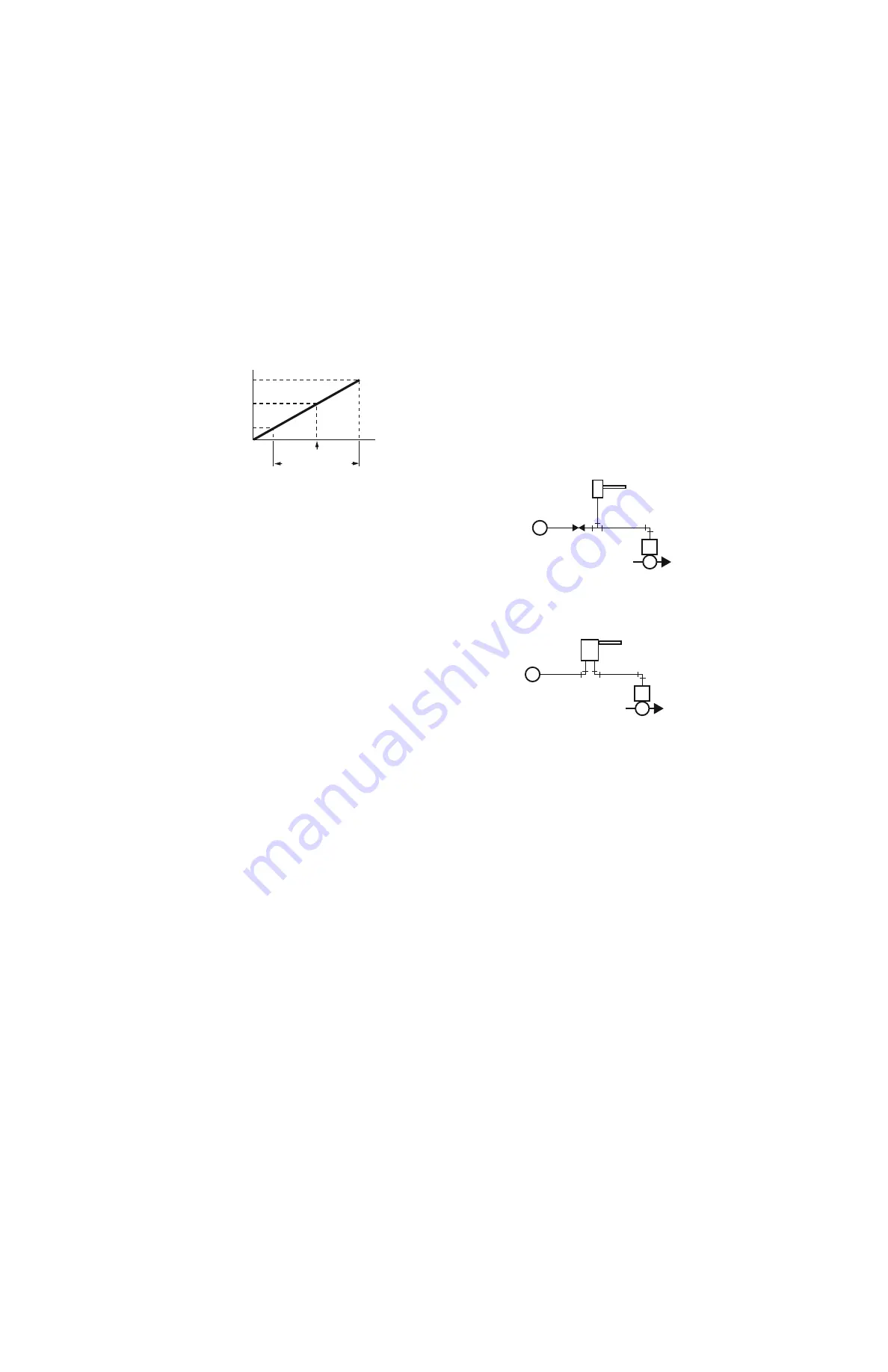

Bleed-type controllers can be used in one-pipe or two-pipe

configurations. In a one-pipe system (Fig. 18), the main air goes

through a restrictor to the controller and actuator in the most

expeditious routing. In a two-pipe system (Fig. 19), the main air

goes into the controller, through an internal restrictor in the

controller, and out of the controller through a branchline to the

actuator. All pilot-bleed and feed-and-bleed controllers are two

pipe.

Fig. 18. One-Pipe Controller System.

Fig. 19. Two-Pipe Controller System.

Controllers may also be classified as single-pressure or two-

pressure controllers. Single-pressure controllers use a constant

main air pressure. Two-pressure controllers use a main air

pressure that is alternately switched between two pressures,

such as 13 and 18 psi. For example, occupied/unoccupied

controllers automatically change setpoint from a occupied

setting at a mainline pressure of 13 psi to a lowered unoccupied

setting at 18 psi. Heating/cooling controllers change from

reverse acting at mainline air pressure of 13 psi for cooling to

direct acting at 18 psi for heating.

Temperature Controllers

Temperature controllers can be one- or two-pipe. The sensing

element is typically bimetal, liquid filled remote bulb, or liquid

filled averaging capillary tube. Dimensional change of the

element with temperature change results in flapper position

change and therefore, pilot and branch pressure change.

Humidity Controllers

Principles that apply to temperature controllers also apply to

humidity controllers. The primary difference between

temperature and humidity controllers is in the type of sensing

element. The sensing element in a humidistat is usually a band

of moisture-sensitive nylon. The nylon expands and contracts

with changes in the relative humidity of the air.

THROTTLING RANGE

0

3

8

13

SETPOINT

NOTE: SETPOINT IS AT MIDDLE OF

THROTTING

RANGE

BRANCHLINE PRESSURE (PSI)

C1091

C2342

MAIN

BRANCH

VALVE

CONTROLLER

M

C2343

MAIN

BRANCH

VALVE

CONTROLLER

M B

M

Содержание VP525C

Страница 58: ...50 customer honeywell com 70 6925 ...

Страница 120: ...112 customer honeywell com 70 6925 ...

Страница 166: ...158 customer honeywell com 70 6925 ...