S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

15

69-1955

SETTINGS AND ADJUSTMENTS

DIP Switch (S1) Settings

When replacing an existing ignition control with the

S8610U, refer to Table 2 on page 2 for the correct DIP

switch settings.

NOTE: Refer to Table 11 for lockout control of DIP

switch timing settings.

IMPORTANT

Do not power the ignition control prior to setting

the DIP switches.

The following timing parameters may be set with this

2-position DIP switch.

Prepurge

To select Prepurge, set

SW1

according to Table 10.

Trial for Ignition (TFI)

To select the Trial for Ignition timing, set

SW2

according to

NOTE: The default factory settings (all OFF) are in

Bold

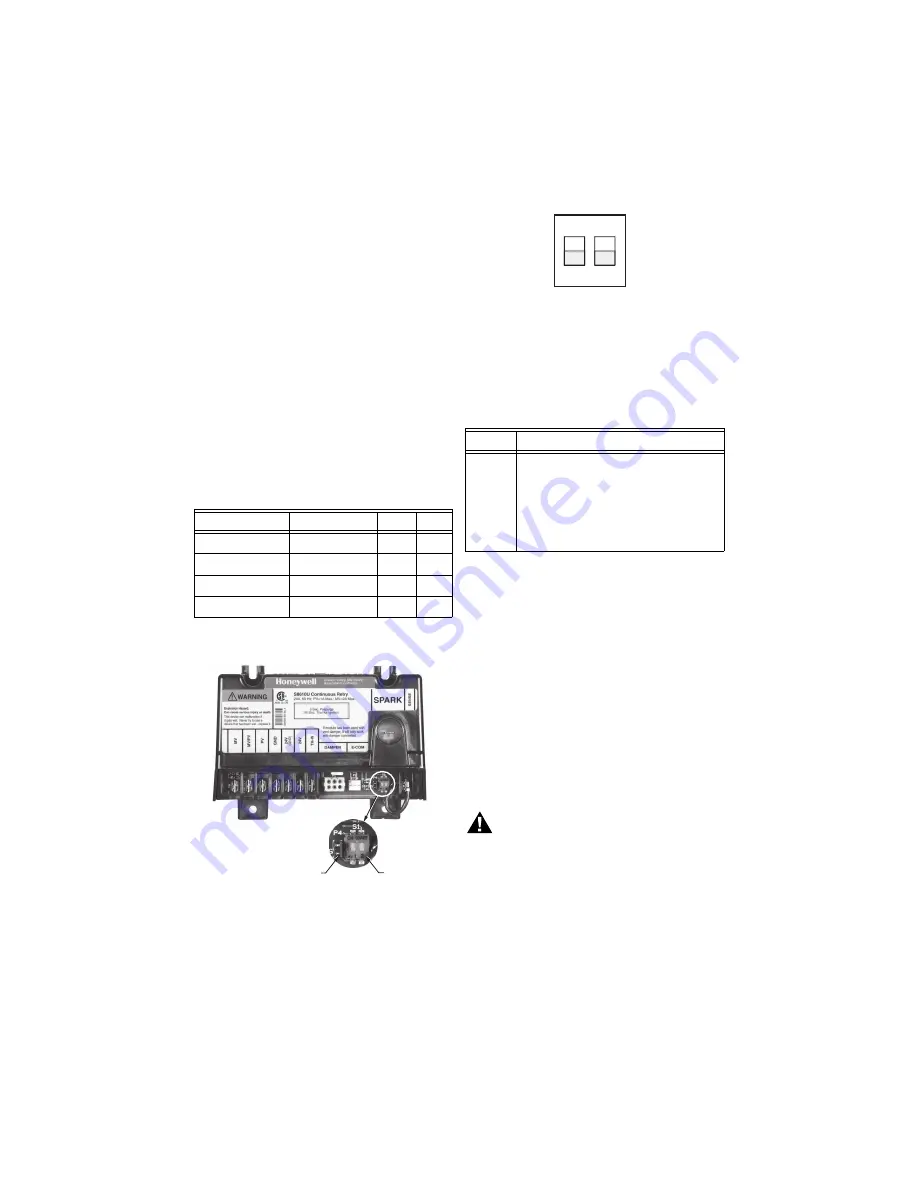

Fig. 6. DIP Switch (S1) and Jumper (P4) Location.

Fig. 7. DIP Switch (S1) - shown with factory default

settings (OFF) for SW1 and SW2.

Jumper

This jumper (labeled P4) is used to lock the operating

sequence selected by the DIP switch settings. See Fig. 6

for jumper location.

IMPORTANT

Once the Jumper has been pulled or the module

starts the 10

th

“Call for Heat”, the control operat-

ing sequence is permanently locked and cannot

be reset by replacing the jumper or by resetting

the Dip Switch.

CHECKOUT

Check out the gas control system:

• At initial installation of the appliance.

• As part of regular maintenance procedures.

Maintenance intervals are determined by the

application.

For additional information, See “Planning the

Installation” on page 4.

• As the first step in troubleshooting.

• Any time work is done on the system.

WARNING

Fire or Explosion Hazard.

Failure to heed these warnings may cause fire

or explosion with property damage, injury, or

loss of life.

1. If you smell gas or suspect a gas leak, turn off

gas at manual service valve and evacuate the

building. Do not try to light any appliance, do

not touch any electrical switch or telephone in

the building until you are sure no spilled gas

remains.

2. Gas leak test must be done as described in the

steps below on initial installation and any time

work is done involving the gas piping.

Table 10. DIP Switch (S1) Settings.

Prepurge

Trial For Ignition

SW1

SW2

None

90 seconds

OFF

OFF

30 seconds

90 seconds

ON

OFF

None

15 seconds

OFF

ON

30 seconds

15 seconds

ON

ON

M23618

S1 DIP SWITCH

P4 JUMPER

Table 11. Jumper Usage.

Jumper

Action to lock the control’s operating sequence

P4

To ensure proper system operation (after

installation and checkout), pull jumper to

lock the DIP switch settings.

NOTE: If jumper is not removed during

installation, the ignition control

locks the DIP switch settings after

the 10

th

“Call for Heat” cycle.

ON

1

2

S1

M23587