GB-6

D

GB

F

NL

I

E

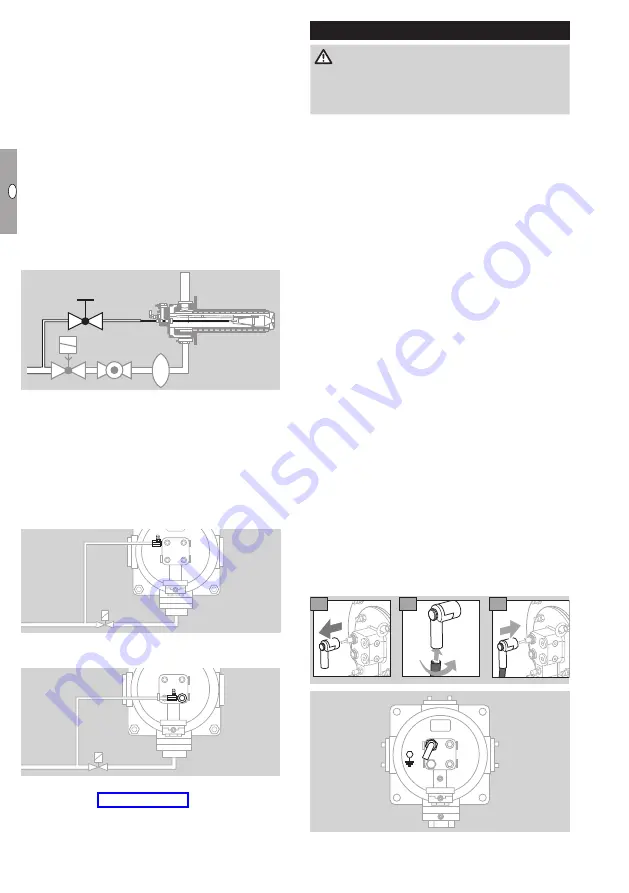

Restrictors

▷

The appropriate restrictors are to be fitted in the

supply lines for fuel gas, combustion air and

motive air for the eductor to adjust the burner.

Central air connection for LPG operation

▷

The LPG version of the burner has an additional

central air lance.

▷

The gas lance must be cooled to prevent the

gas cracking and soot forming inside the burner.

▷

The connection is made with an Ermeto pipe.

▷

The purge air connection must be located in the

air supply line to the burner upstream of the air

control valve, for example at the inlet of the air

solenoid valve.

▷

Open the adjuster in the central air lance fully;

on ECOMAX

®

1, the adjuster must be restricted

to 45° or 50%.

Purge air connections for electrode and UV

sensor

▷

The electrode and the UV sensor should be

cooled and purged with air.

▷

The air must be branched off upstream of the

air control valve, for example at the inlet of the

air solenoid valve.

▷

Connect the purge air to the gas flange next to

the electrode.

▷

In the case of UV control, use the purge air con-

nection of the UV sensor.

▷

The nozzles are adapted to the relevant burner,

see page 16 (Accessories). The nozzles do

not need any adjustment.

Wiring

DANGER

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is discon-

nected from the power supply.

▷

The flame is monitored by a combined flame

rod/spark electrode as standard on the burner

ECOMAX

®

.

▷

Flame control with a UV sensor is necessary if a

furnace temperature of 1050°C is exceeded for

direct heating or 950°C for indirect heating. In

this case, we recommend a UV sensor UVS 10

with a purge air connection be used.

▷

An adapter set (Order No. 21800791), which

must be ordered separately, is available for in-

stalling the UVS 10. If the adapter set has been

ordered with the burner, it is fitted to the burner

on delivery and the UV sensor can be screwed

on to it.

▷

For high temperature operation without flame

control using ionization or a UV sensor, the air

flow must be monitored by a pressure switch.

▷

We recommend an ignition transformer ≥ 7.5 kW,

≥ 20 mA.

▷

For the ignition/ionization cable, use (unscreened)

high-voltage cable:

FZLSi 1/6 up to 180°C (356°F),

Order No. 04250410, or

FZLK 1/7 up to 80°C (176°F),

Order No. 04250409.

▷

Length of cable: max. 5 m, recommended < 1 m.

▷

Lay cable individually and not in a metal conduit.

▷

Install cable well away from mains cables and

interference from electro-magnetic sources.

▷

In particular, avoid external electrical interference

when using ionization control.

▷

For UV control, route the ignition cable separately

from the UV cable.

1

3

2