GB

MU0H-1155GE23 R0319

5

•

The filter must be cleaned by reverse rinsing regularly,

at least every 2 months

•

Non-compliance can lead to the filter becoming blocked

This results in a drop in pressure and decreased water

flow

•

The filter meshes are made of stainless steel. A red

coating as a consequence of rust from the pipelines has

no influence on function or the way the filter works

Do not forget to do a visual check of the ball valve.

Replace if it is dripping!

8.1.3 Pressure reducing valve

CAUTION!

Interval: once a year

1.

Close shut-off valve on outlet

2.

Check outlet pressure using a pressure meter when

there is zero through-flow

•

If the pressure is increasing slowly, the valve may

be dirty or defective. In this instance, carry out

servicing and cleaning

3.

Slowly open shut-off valve on outlet

8.2 Maintenance

Frequency: every 1-3 years (depending on local

operating conditions). To be carried out by an

installation company

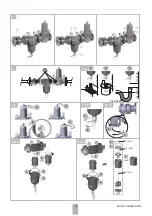

8.2.1 Check valve

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Replace check valve

5.

Slowly open shut-off valves on inlet and outlet

8.2.2 Filter

8.2.3 Replace filter insert

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Unscrew filter bowl

5.

Remove filter insert

6.

Insert new filter insert

•

Put on the O-ring

7.

Put new O-ring on filter bowl

8.

Screw filter bowl in place

9.

Slowly open shut-off valve on inlet

10. Slowly open shut-off valve on outlet

8.2.4 Replace filter mesh

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Unscrew filter bowl

5.

Remove filter insert

6.

Dismount filter insert

7.

Replace filter mesh

8.

Mount the filter insert

9.

Put filter insert into filter bowl

10. Put new O-ring on filter bowl

11. Screw filter bowl in place

12. Slowly open shut-off valve on inlet

13. Slowly open shut-off valve on outlet

8.2.5 Replace ball valve

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Unscrew discharge connection

5.

Remove ball valve

6.

Screw in new ball valve

7.

Screw in discharge connection

8.

Slowly open shut-off valve on inlet

9.

Slowly open shut-off valve on outlet

8.2.6 Pressure reducing valve

CAUTION!

Frequency: every 1-3 years (depending on local

operating conditions). To be carried out by an

installation company

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Loosen hexagon nut on spring bonnet

CAUTION!

There is a spring in the spring bonnet. It may cause

injuries if the spring is derailing.

• Make sure tension in compression spring is

slakkened!

5.

Slacken tension in compression spring

•

Turn control adjustment screw to the left (-) until it

does not move any more

6.

Unscrew spring bonnet

7.

Check the cartridge insert for fault-free condition and

replace insert or sealing parts if necessary.

8.

Reassemble in reverse order