10

4.

BEFORE OPERATION CHECKS

_____________________________________________________________________________

For your safety and to maximize the service life of your equipment, it is very important to take a few moments

before you operate the drill to check its conditions. Be sure to take care of any problem you find, or have your

servicing dealer correct it, before you operate the drill.

Improperly maintaining this product, or failure o correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or killed.

Before beginning your pre-operation checks, be sure the engine in level and the engine switch is in the OFF

position.

ALWAYS check the following items before you start the engine:

1.

Look around and underneath the engine for signs of oil or petrolleaks.

2.

Remove any excessive dirt or debris, especially around the muffler nad recoil starter.

3.

Look for signs of damage.

4.

Check that all shields and covers are in place, and all nuts, bolts and screws are tightened.

C

HECK THE ENGINE

1.

Check the fuel level (see ”Refueling”). Starting with a full tank will help to eliminate or reduce operating

interruptions for refueling.

2.

Check the engine oil level (see ”Oil level check”). Running the engine with a low oil level can cause

engine damage.

3.

Check the air filter element (see “Air cleaner”). A dirty air filter element will restrict air flow to the

carburetor, reducing engine performance.

C

HECK THE IMPACT MECHANISM

1.

A damaged dust protection cap should be changed immediately. We recommend having this carried out

by an after-sales service.

2.

To provide safe and good operations, check that the tools are cleaned.

3.

Check that the impact mechanism is free of oil leaks. In this case consult an after-sales service for a

complete check.

4.

Setting the auxiliary handle.

If, despite the accurate checks, the impact mechanism should fails, the repair must be carried out by an

authorized after-sales service.

5.

OPERATION

_______________________________________________________________________________________________________

Before operating the drill for the first time, please review the “Safety information 1.4 ” and “Before operation

checks 4”.

CARBON

MONOXIDE

GAS

IS

TOXIC.

BREATHING

IT

CAN

CAUSE

UNCONSCIOUSNESS

AND

EVEN

KILL

YOU.

AVOID

ANY

AREAS

OR

ACTIONS

THAT

EXPOSE

YOU

TO

CARBON

MONOXIDE.

5.1

STARTING THE ENGINE

1.

To start a cold engine, move the choke lever to the CLOSED position.

2.

To restart a warm engine, leave the choke lever in the OPEN position.

3.

Press the priming bulb repeatedly until fuel can be seen in the clear-plastic fuel-return tube.

4.

Turn the handle switch in the ON position.

5.

Pull the starter grip lightly until you feel resistance, then pull briskly. Return the starter grip gently.

If the choke lever was moved to the CLOSED position to start the engine, gradually move it to the

OPEN position as the engine warms up.

Содержание 11985

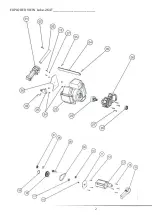

Страница 2: ...2 EXPLODED VIEW Loke 26 4T_______________________________________ ...

Страница 3: ...3 EXPLODED VIEW Balder 36 4T_______________________________________ ...

Страница 8: ...8 3 COMPONENT AND CONTROL LOCATION________________________________________________________________ ...

Страница 20: ...20 Blinken a s Østkilen 4 1621 Gressvik Tlf 90 70 11 00 Fax 69 36 09 20 www blinken no ...