--- 34 ---

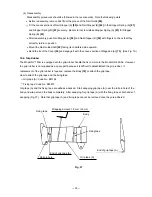

Apply grease to the O-ring sliding surface of the Feed Piston [64] and the Nose [22]. However, be careful

not to apply too much grease to the "A" surface shown in Fig. 25. Otherwise, the Feed Piston [64]

operates improperly at the low pressure.

Mount the Roll Pin D4 x 16 [25] facing its split toward the magazine as shown in Fig. 25. The amount of

protrusion at both ends must be equal after reassembly (amount of protrusion: 1.5 mm).

Check that the Retaining Ring for D28 Hole [68] is securely inserted into the groove of the Nose [22].

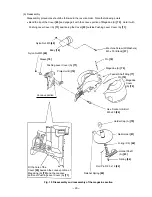

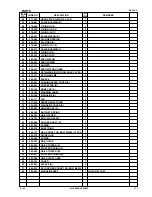

(4) Disassembly and reassembly of Nail Guide [89], Nail Stopper (A) [90], Nail Stopper (B) [92] and other parts

(See Fig. 26.)

Tools required: Flat-blade screwdriver

Hex. bar wrench 3 mm

(a) Disassembly

Remove the Shaft Ring [85] from the Nail Guide Shaft [29] with a flat-blade screwdriver and remove the

Nail Guide Shaft [29]. Then the Nail Guide [89] and other parts can be removed in an assembly.

Remove the Nylock Hex. Socket Hd. Bolt M4 x 12 [97] with a hex. bar wrench 3 mm. Then the Nail Guide

Cover [94], Stopper Spring (A) [91], Stopper Spring (B) [93] and Cover [95] can be removed.

Remove the Shaft Ring [85] from the Guide Lock [87] with a flat-blade screwdriver and pull out the Guide

Lock [87]. Then Nail Stopper (A) [90] and Nail Stopper (B) [92] can be removed.

Nose [22]

Shaft Ring [85]

Cover [95]

Nail Guide Cover [94]

O-ring (P-4) [21]

Nail Guide Shaft [29]

Nylock Hex. Socket Hd. Bolt M4 x 12 [97]

Sleeve (B) [96]

Shaft Ring [85]

Stopper Spring (B) [93]

Nail Stopper (B) [92]

Stopper Spring (A) [91]

Nail Stopper (A) [90]

Guide Lock [87]

Nail Guide [89]

Spring [88]

Fig. 26 Disassembly and reassembly of nail guide, nail stopper (A), nail stopper (B) and other parts

Содержание NV 75AG

Страница 45: ......