SAFETY PRECAUTIONS (Continued)

●

When charging a refill of ink or makeup, exchanging ink, or

otherwise handling ink or makeup, take enough care not to spill

ink or makeup.

If you spill any ink or makeup by mistake, wipe it off neatly and

promptly with wiping paper or something similar. Do not close the

maintenance cover until you make sure that the portion you have

just wiped is completely dry.

You must pay particular attention when you have spilled ink or

makeup inside the printer and it is not completely dry. Why?

Because vapors of ink or makeup will stay inside the printer and

may catch on or cause a fire.

If you find it hard to wipe the printer when it is turned on, stop it with the

maintenance cover open. Power it down, and then wipe it off again.

●

If you wish to clean the casing of the printer with wiping paper

impregnated with makeup, be sure to do so with the power off.

Attempting to clean it when the power is on will cause makeup or vapors of

makeup to enter the printer, possibly catching on or causing a fire.

When the cleaning is over, open the maintenance cover and make sure that no

makeup has entered and no vapors remain inside.

●

Should you find a leak of ink or makeup inside the printer while the

printer is running or being maintained, wipe it off promptly with

wiping paper or something similar. Then, with the maintenance

cover open, stop the printer, power it down, and repair the leak.

Continuing operation with a leak of ink or makeup will cause an anomaly,

resulting in abnormal printing.

Ink and makeup are flammable. They may therefore catch on or cause a fire.

●

If you wish to receive ink particles in a beaker, for a printing test

for example, use an electrically conductive beaker and connect the

beaker securely to the ground.

Do not let the tip of the printing head enter the beaker.

Ink particles used for printing are electrically charged. An ungrounded beaker has

a gradually rising charge, possibly catching on or causing a fire.

●

Ensure that all electrical wiring, connections and grounding comply

with applicable codes. Properly connect the printer to its dedicated

ground.

Failure to do so could result in electrical shock or fire.

●

When welding, keep enough space between the IJ printer and the

welding work area to prevent the arc from starting a fire. Also, be

sure to insulate the print head and IJ printer frame to keep the

welding current from flowing to the control section of the printer,

and to make a separate ground connection for the printer.

Exercise caution to avoid electric shock and fire.

WARNING

1-4

Содержание IJ PH

Страница 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Страница 2: ... Revision of PH service manual Revision Chapter Revised Page ...

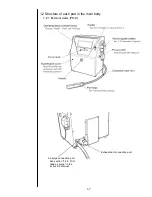

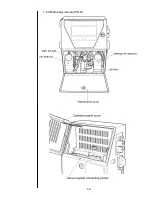

Страница 13: ...1 2 2 Main body internal PH D 1 8 ...

Страница 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Страница 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Страница 202: ...7 2 7 2 Electrical Connection Diagram ...

Страница 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...