4-30

4.12 Repairing Method When the Circulation Route Is Dry or Sticks

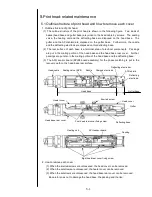

4.12.1 Cleaning method for the solenoid valve

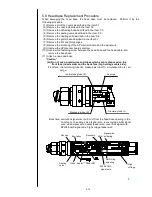

1 Remove the sticking solenoid valve.

(Refer to “4.6 Solenoid Valves Replacement Procedure)

2 Connect the connector of the target solenoid valve.

3 Inject the makeup ink with the flush bottle from the holes shown in the

following figure until it overflows and leave for about 10 minutes.

4 Operate the target solenoid valve repeatedly about 10 times on the

“Solenoid Valve/Pump Test” screen. If an operation sound can be

confirmed, the repair work is completed. If not, replace the solenoid

valve.

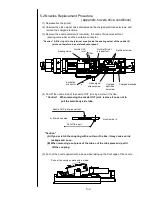

4.12.2 Repairing method for the supply pump

1 Remove the tube connecting block of the ink reservoir and connect the

hand pump.

2 Operate the pump, MV2, and MV6 in this order on the “Solenoid

Valve/Pump Test” screen.

3 Apply pressure with the hand pump.

4 If the makeup ink of the hand pump flows to the pipe M, the repair work is

completed. If the supply pump cannot be repaired in about 10 minutes,

replace the pump unit.

Pipe

Pipe[M]

Hand pump

Hand pump specifications

Part name : Nozzle cleaning assembly

Parts No :451000

Hole (4 positions)

Содержание IJ PH

Страница 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Страница 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Страница 13: ...1 2 2 Main body internal PH D 1 8 ...

Страница 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Страница 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Страница 202: ...7 2 7 2 Electrical Connection Diagram ...

Страница 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...