CLEANING BRUSH HEAD BRUSHES (SCRUBBING)

Careful cleaning of the brush guarantees better cleaning of the floor as well as a longer brush head gearmotor lifespan. To clean the brush, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible contact with the edges or tips of metal objects.

3.

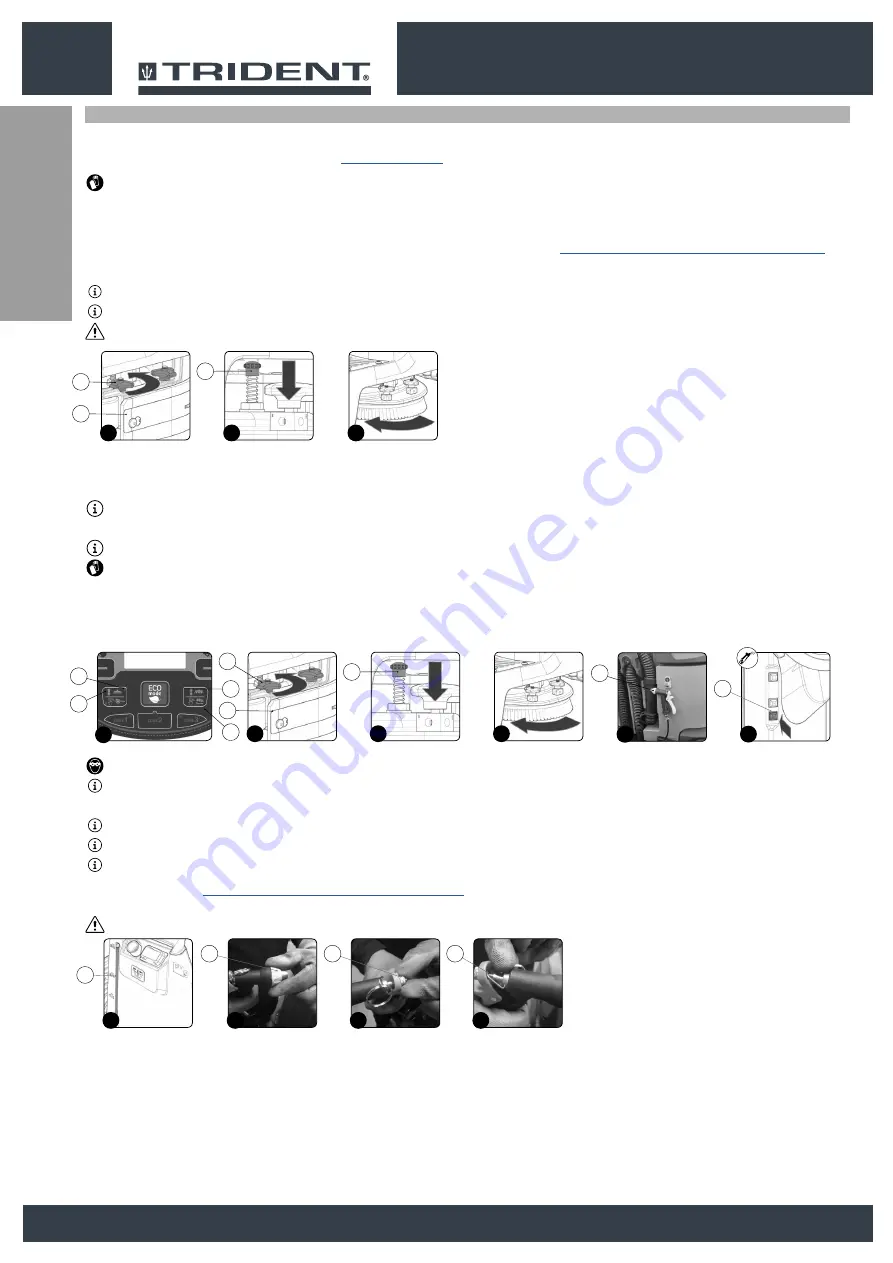

Move to the left side of the machine and remove the left splash guard (1), first remember to completely unscrew the knobs (2) present on the brush head body (

Fig.1

).

4. Press the brush locking pin (3) (

Fig.2

).

5. Keeping the pin (3) pressed, turn the brush clockwise until it is released (

Fig.3

).

6. Turn until the button is pushed towards the outside of the coupling spring and is locked into place.

7. Clean the brush under a stream of running water to remove any impurities from its bristles. Check the wear status of the bristles and replace the brushes if they are excessively consumed (the bristles'

protrusion must not be less than 10 mm; this distance is indicated on the brush by the yellow band). Read the paragraph “

ASSEMBLING THE BRUSH HEAD BRUSH (DUAL-BRUSH VERSION)

replacing the brushes.

8. After checking to make sure that the brush is clean, reassemble it and move on to the one on the right hand side.

N.B.

: you are advised to invert the right and left-hand brushes every day.

N.B.

: The image in

Fig.3

indicates the direction of rotation for uncoupling the left brush; the right brush must be turned in the opposite direction.

ATTENTION:

If the brushes are not new however, and have deformed bristles, it is better to reassemble them in the same position (the right-hand one on the right, and the left-hand one on the left), to

prevent the different inclination of the bristles producing an overload on the brush motor as well as excessive vibrations.

To clean the brush with the spray gun kit, proceed as follows:

1. Take the machine to the maintenance area.

2. Lift the brush head body and press the “BRUSH HEAD CONTROL” button (1) on the control panel (

Fig.1

).

N.B.

:

as soon as the button (1) on the control panel is pressed, the green LED (2) (“BRUSH HEAD BODY WORK POSITION”) will switch off (

Fig.1

).

3. Lift the squeegee body and press the “SQUEEGEE CONTROL” button (3) on the control panel (

Fig.1

).

N.B.

:

as soon as the button (3) on the control panel is pressed, the green LED (4) (“SQUEEGEE BODY WORK POSITION”) will switch off (

Fig.1

).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible contact with the edges or tips of metal objects.

4.

Move to the left side of the machine and remove the left splash guard (5), first remember to completely unscrew the knobs (6) present on the brush head body (

Fig.2

).

5. Press the brush locking pin (7) (

Fig.3

).

6. Keeping the pin (7) pressed, turn the brush clockwise until it is locked (

Fig.4

).

7. Turn until the button is pushed towards the outside of the coupling spring and is locked into place.

8. Release the tank cleaning accessory (8) (at the back of the machine) from the retainers (

Fig.5

).

9.

Activate the optional tank cleaning kit on/off pump by pressing the button (9) on the back of the machine (

Fig.6

).

CAUTION

: when using the optional tank cleaning kit, you are advised to always wear goggles to avoid any risk of serious injury to your eyes.

N.B.

: Before activating the optional tank cleaning kit, check the level indicator (10) to see how much solution there is in the solution tank (

Fig.7

).

10. Activate the solution jet by pressing the lever in the tank cleaning accessory.

N.B.

: To adjust the solution jet from the

tank cleaning accessory, turn the knob (11) on the accessory itself

(

Fig.8

).

N.B.

: To adjust the intensity of the solution jet from the

tank cleaning accessory, turn the knob (12) on the accessory itself

(

Fig.9

).

N.B.

: To stop the solution jet,

use the lever (13) on the tank cleaning accessory

(

Fig.10

).

11. Clean the brush under running water to remove any impurities from its bristles. Check that the bristles are not worn; in the event of excessive wear, replace the brush (the bristles should be at least 10 mm

ASSEMBLING THE BRUSH HEAD BRUSH (DUAL-BRUSH VERSION)

” when replacing the brush.

12. After checking to make sure that the brush is clean, reassemble it and move on to the one on the right hand side.

ATTENTION

: the place designated for this operation must comply with current environmental protection regulations.

3

2

1

2

1

3

4

3

2

6

5

7

1

4

2

3

1

5

8

6

9

10

13

7

8

10

11

9

12

22

Содержание TRIDENT R26SC PRO

Страница 2: ......

Страница 3: ...ENGLISH 4 ESPA OLA 30 FRAN AIS 56 3 ESPA OLA FRAN AIS ENGLISH...

Страница 82: ...ESPA OLA FRAN AIS ENGLISH 82...

Страница 83: ......

Страница 84: ...HILLYARD INDUSTRIES PO Box 909 St Joseph Missouri 64502 0909 U S A Telephone 816 233 1321 www hillyard com...