TNC 426/TNC 425/TNC 415 B/TNC 407

5 - 4 2

5

Programming Tool Movements

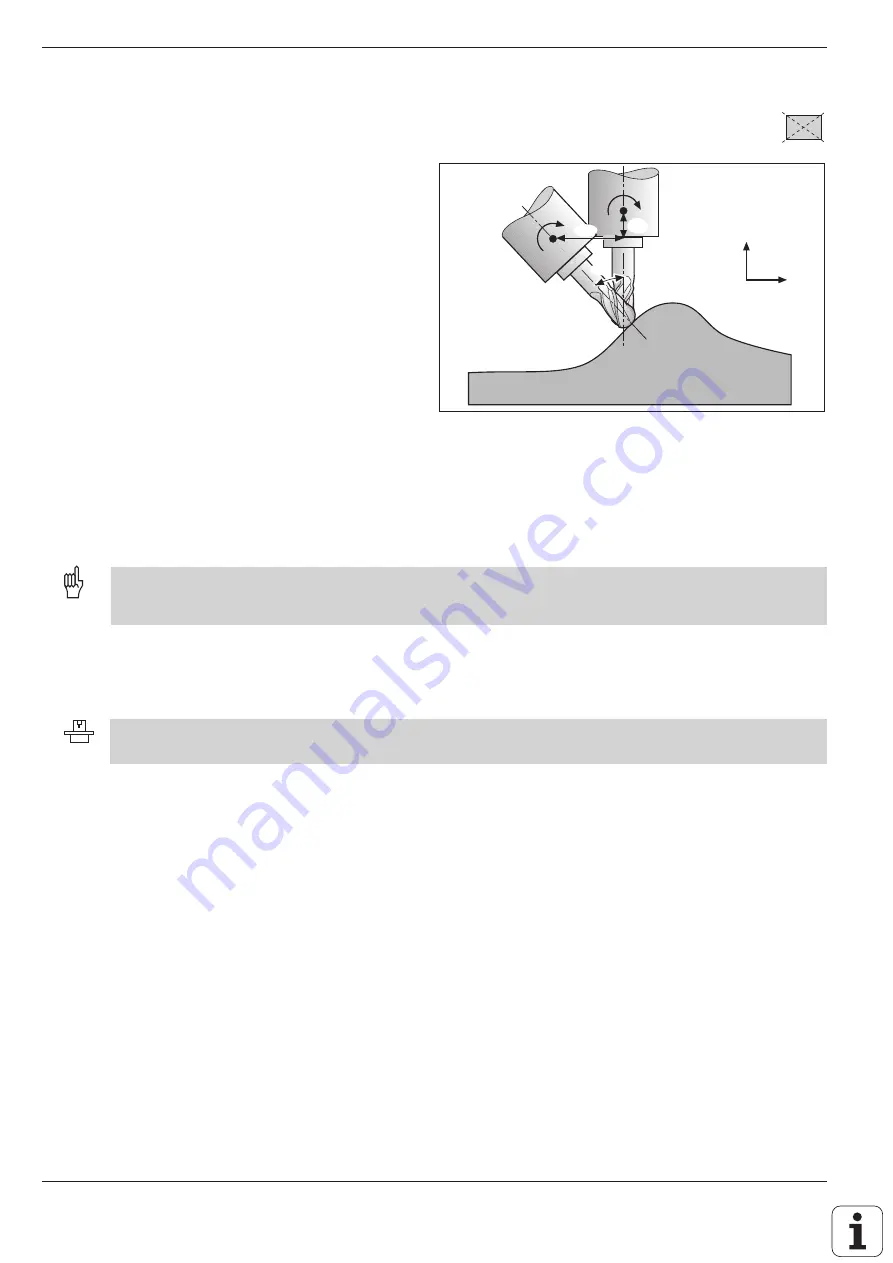

Fig. 5.51:

Offset of the tool datum for tilting the tool

M Functions for Contouring Behavior

B

dz

Z

X

B

dx

dB

The machine geometry must be defined by the machine manufacturer in machine parameters MP7510 and

following.

Automatic compensation of machine geometry when working with tilted axes: M114

Standard behavior – without M114

The TNC moves the tool to the positions given in

the part program. The tool offset resulting from a

tilted axis and the machine geometry must be

calculated by a postprocessor.

Automatic compensation of machine

geometry – with M114

The TNC compensates the tool offset resulting

from positioning with tilted axes (such as dx and dz

in Fig. 5.51). It calculates a 3D length compensa-

tion. The radius compensation must be calculated

by a CAD system or by a postprocessor. A

programmed radius compensation (RL or RR)

results in the error message ILLEGAL NC BLOCK.

Thus if you write the NC program with a

postprocessor, the machine geometry does not

have to be calculated.

If the tool length compensation is calculated by the

TNC, the programmed feed rate refers to the point

of the tool; otherwise, it refers to the tool datum.

If you are working with a swivel head under program control, you can interrupt program run and change the position

of the tilt axis (for example, with the electronic handwheel.) Use the RESTORE POS AT N function (block scan, see

page 3-8) to return to the point of interruption. The TNC automatically calculates the new tilt axis position.

Cancelling

M114 is cancelled by M115 or by a N99999 block.

407