59

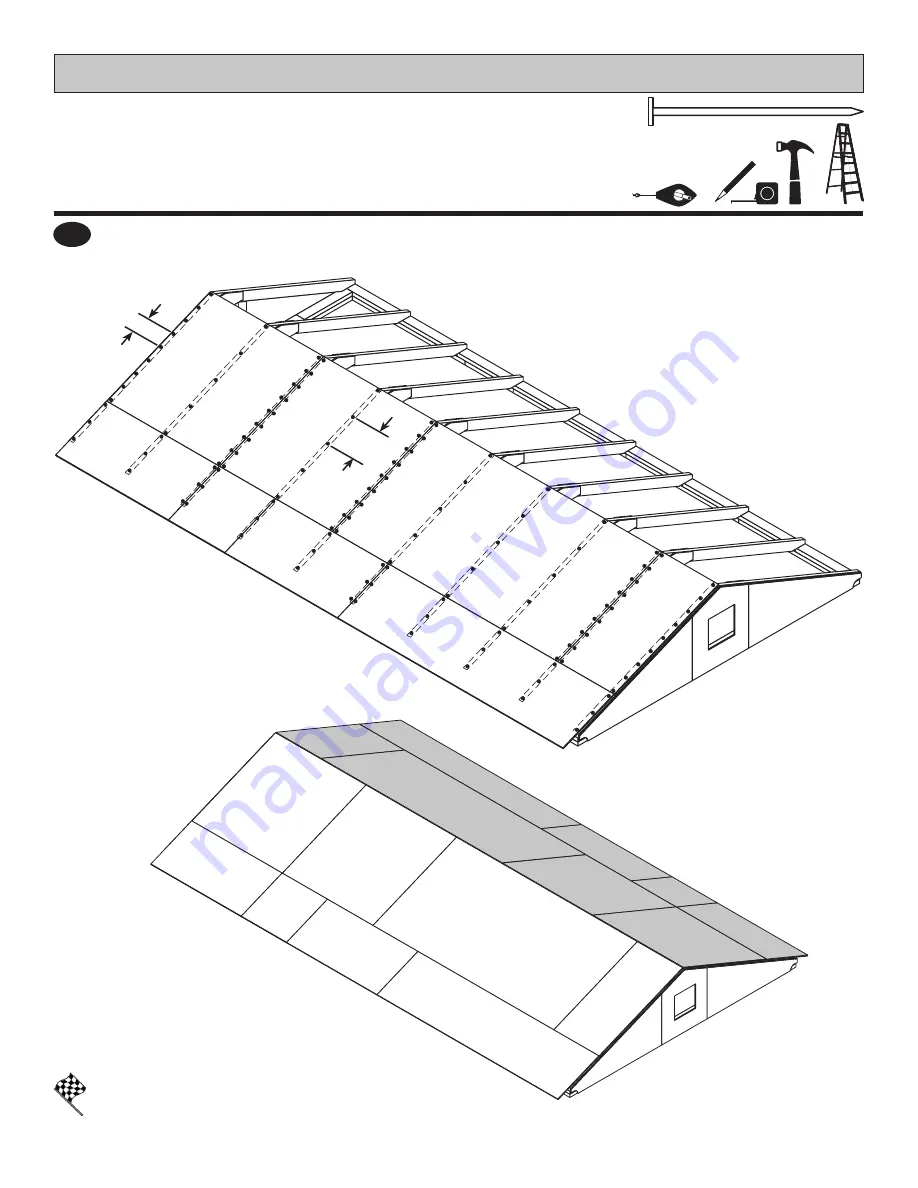

Your roof panels are now installed.

Repeat all steps to install roof panels

on the opposite side.

FINISH

Secure all roof panels with 2" nails spaced 6" apart and 12" apart inside of the upper panels.

9

PARTS REQUIRED:

10' x 18' ROOF PANELS

2" (5,1 cm)

6"

(15,2 cm)

12"

(30,5 cm)

x230