95

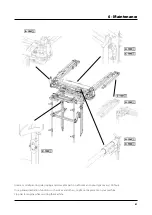

6 - Maintenance

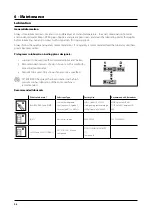

Grease Gun Calibration

Before lubricating the sprayer, you must calibrate your grease gun to ensure that the correct amount of grease is applied

to each lubrication point. The correct amount of grease applied will prolong the lifetime of the sprayer.

Calibration example

1. Insert the correct grease cartridge in your grease gun.

2. Apply grease onto a tissue or a piece of paper. Complete 10 full

strokes of the grease gun.

3. Place the paper with grease on a scale.

4. If your grease pile weighs for example 10 grams (A), then 1

stroke equals 1 gram of grease.

When calibrated you can count how many strokes to complete, when

lubricating the different grease points on the sprayer according to the

specifications.

Alternative method

1. Count the strokes, until you have 10 grams of grease piled up

on the scale (A).

2. Now you can figure out how many strokes to use for applying a

certain amount of grease to a lubrication point.

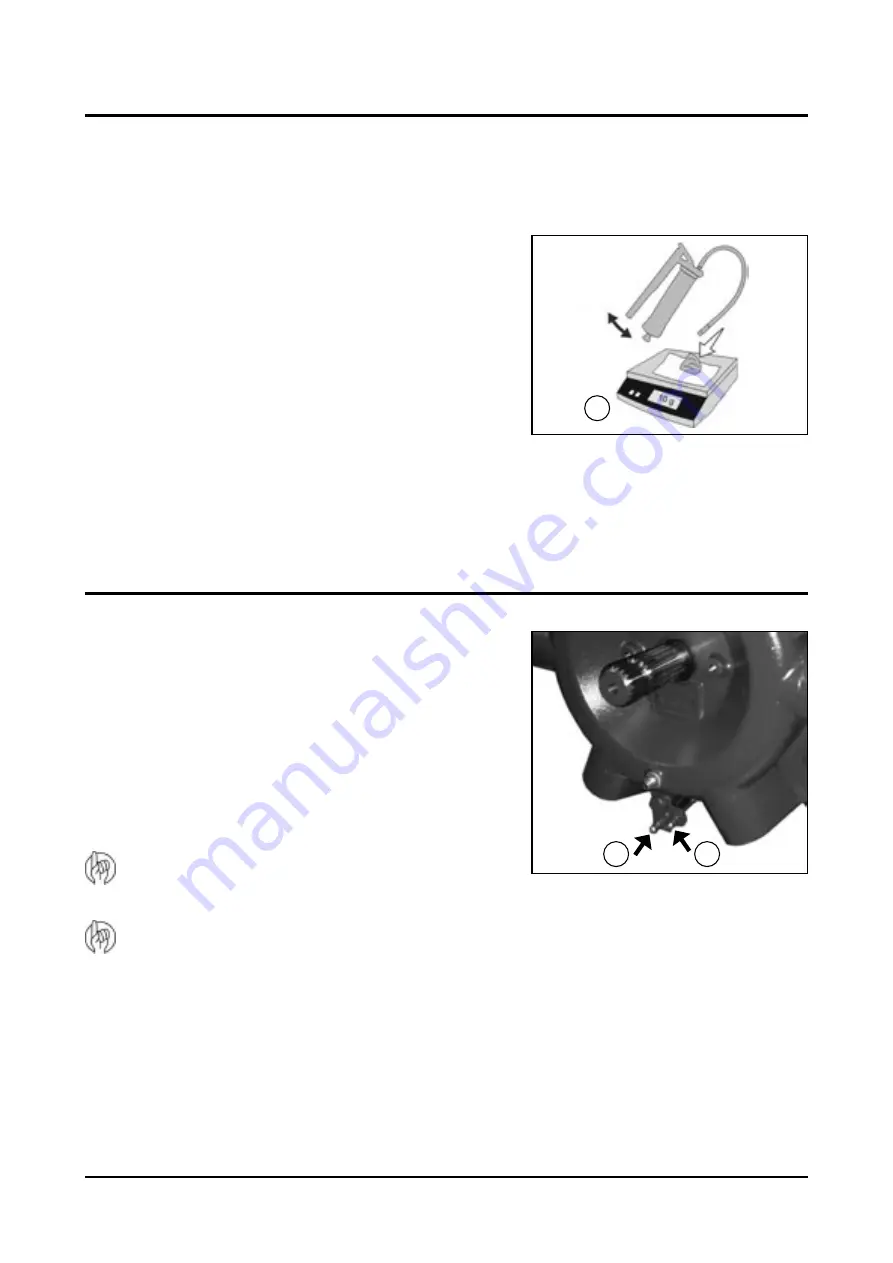

Greasing the Pump

The pump is greased as follows:

1. Factory greased:

300 g grease into each lubrication point (A).

2. Normal operation:

MUST be greased every 50 hours with 30 g grease into each

lubrication point (A).

3. After disassembling the pump (diaphragm renewal, etc.):

MUST be greased with 200 g grease into each lubrication point

(A).

ATTENTION! In order to avoid excessive wear it is important to

use a recommended lubricant! See “Recommended lubricants”

on page 4.

ATTENTION! The pump MUST be stopped during greasing!

A

10 x

A

A

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...