89

6 - Maintenance

Occasional maintenance

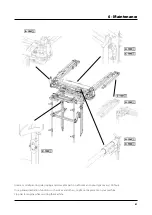

Replacing the 321 valves and diaphragms

Diaphragms

Dismantle the crankcase (4). Now, the diaphragm (5) can be replaced.

Grease the pump if the liquid has leaked to the inside. Make sure that

the draining hole is not obstructed. Reassemble the pump again.

Torque settings for the 321 are:

Cranckcase: 60 Nm / 44.4 lbft.

Crankshaft: 70 Nm / 51.8 lbft.

Diaphragm screws: 60 Nm / 44.4 lbft.

WARNING! Before assembling the covers, turn the shaft with the

hand and make sure that the connecting rods are ascending

and decending respectively. If not change the position of the

connecting rods. The first connecting rod must be assembled

towards the right-hand side.

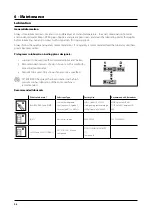

SV operating unit

The SV operating unit open and close via a pilot line as in picture

A, a small piston activated by the solenoid , opens up a small hole,

hereinafter the liquid pressure opens op the larger diaphragm B in the

valve, and allows the liquid to flow to the nozzles.

The pilot line can block due to sedimentation of chemicals.

Unscrew the 4 allen bolt, lift up the piston as in picture A, rinse out and

reassemble.

1

5

4

3

2

A

B

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...