84

6 - Maintenance

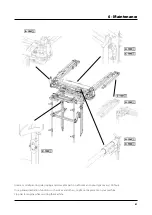

Filters and fittings

Inspect the filters every 50 working hours. Apart from ensuring that they are clean, make sure that the mesh is in good

condition. Otherwise, the effeciency of the filters will be reduced.

Whenever dismantling a filter or hose pipe, take care not to pinch the o-rings fitted to them. When replacing the pipe

fitting, lubricate the o-ring with oil or grease so it seats in the groove.

ATTENTION! If the filter is not in good condition, it could cause numerous unneccesary interruptions during the

working day, extending the working time required.

ATTENTION ! Each time you remove a fitting to check the condition of its o-ring or for any other reason, remember

to lubricate the O-ring with oil or grease to prevent it from being pinched or breaking when reassembling the

fitting in its housing.

ATTENTION! Insufficient greasing of the pump could cause it to overheat and break the moving parts inside.

Winter storage

At the end of the season, some extra time should be dedicated to the equipment before storing it during the winter

time.

It is recommended you store it in a place where it cannot be affected by freezing temperatures. Put at least 10 litres of

anti-freeze covering 33% of the inside of the tank and turn the pump for a few minutes so that the entire circuit is filled

by the solution.

As anti-freeze is an oily solution it also avoids the hoses and all the non-metallic parts from drying up during the period

of time that the equipment will be out of use.

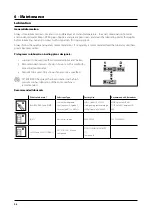

Preparing the equipment for use after storage

After storage, the equipment should be prepared well, thus guaranteeing it is in good condition for the new season. To

do this correctly, follow the steps set out below:

1. Take off the protective canvas cover if you had put one on.

2. Fit the pressure gauge again. Change the old Teflon.

3. Connect the equipment up to the tractor, including the electric cables and hydraulic hoses.

4. Check the hydraulic functions.

5. Drain the remaining anti-freeze from the tank.

6. Completely rinse out the liquid circuit with clean water.

7. Fill the tank with clean water and check all its functions.

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...