5 - Operation

42

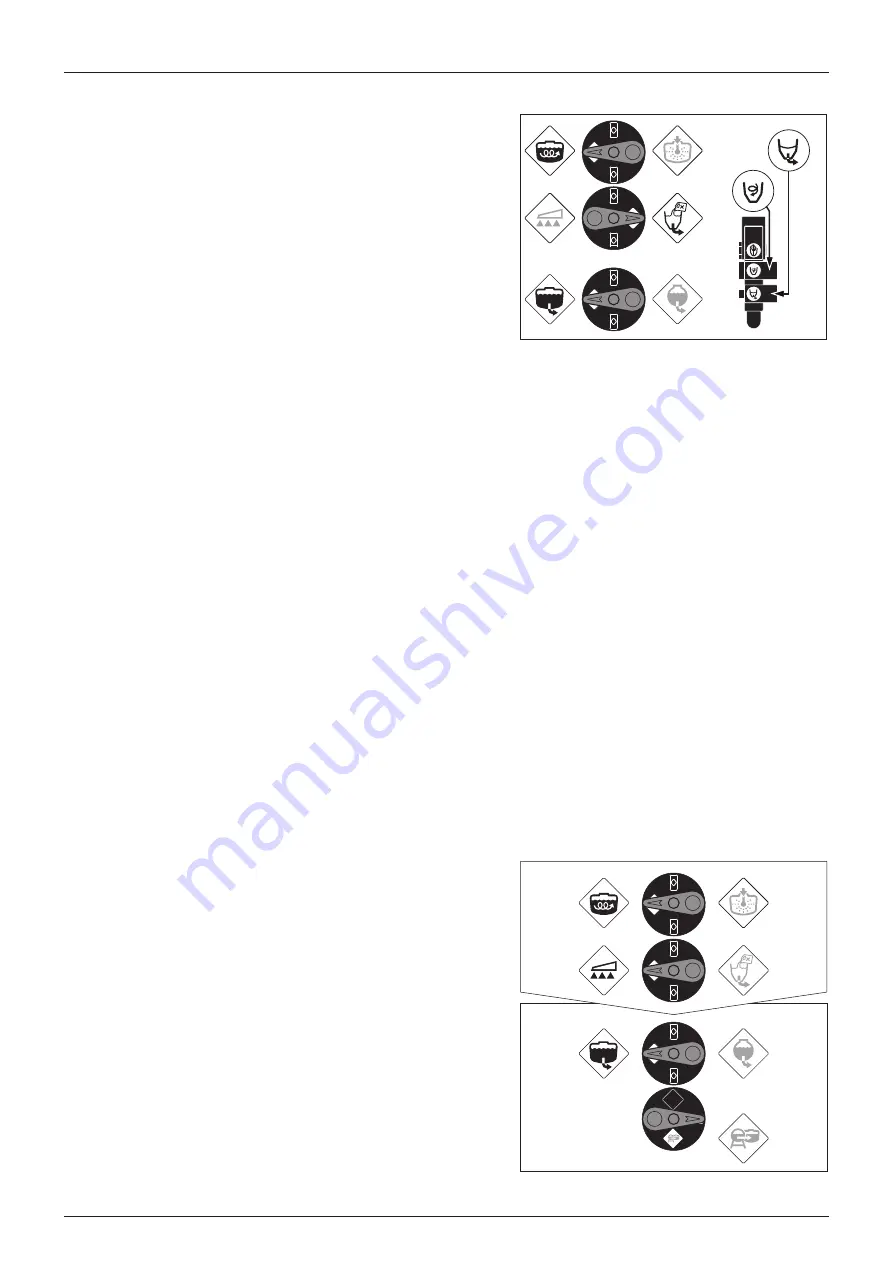

Filling liquid chemicals by HARDI TurboFiller (optional)

1.

Fill the main tank at least 1/3 with water (unless otherwise stated

on the chemical container label).

2.

Turn the handle of the suction valve towards “suction from Main

tank”. Turn pressure valve to“TurboFiller”. Turn the AgitationValve

towards “Agitation” if required.

μ

ATTENTION! For increased suction from the TurboFiller the

AgitationValve can be kept closed.

3.

Engage the pump and set P.T.O. speed at 540 r/min or 1000 r/min

(depending on pump model).

4.

Open TurboFiller lid. Measure the correct quantity of chemical and

fill it into the hopper.

€

DANGER! Always wear face shield and other appropriate personal safety equipment when filling chemicals.

μ

ATTENTION! The scale in the hopper can only be used if the sprayer is parked on level ground! It is recommended to

use a measuring jug for best accuracy.

5.

Engage the hopper transfer device by opening the TurboFiller suction valve and the chemical is being transferred to

the main tank.

μ

ATTENTION! The hopper rinsing device is using spray liquid for rinsing the hopper for concentrated chemical!

Cleaning the TurboFiller must always be done when the spray job is ended and together with the entire sprayer - a

cleaning after the last filling and before spraying the last tankful does not ensure a clean TurboFiller!

6.

If the chemical container is empty, it can be rinsed by the Chemical Container Cleaning device. Place the container

over the multi-hole nozzle and push the upper lever to the left of the TurboFiller.

€

DANGER! In order to avoid spray liquid hitting the operator, do not press lever unless the multi-hole nozzle is covered

by a container as spray liquid may otherwise hit the operator.

7.

Close TurboFiller suction valve when the hopper has been rinsed.

8.

Close the TurboFiller lid.

μ

ATTENTION! Rinsing device uses spray liquid to rinse containers for concentrated chemicals. Always rinse the che-

mical containers with clean water several times until they are clean before disposal.

9.

If closed, turn the AgitationValve towards “Agitation”.

10.

When the spray liquid is well agitated, turn handle of the pressure

valve towards “Spraying” position. Keep P.T.O. engaged so the

spray liquid is continuously agitated until it has been sprayed on

the crop.

Содержание MASTER PRO VHH

Страница 6: ...Table of Contents 6 ...

Страница 8: ...1 EC Declaration 8 ...

Страница 12: ...2 Safety notes 12 ...

Страница 50: ...5 Operation 50 ...

Страница 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Страница 70: ...7 Fault finding 70 ...

Страница 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Страница 77: ...8 Technical specifications 77 Boom hydraulic Y A Option for slanting B Option for single side folding VHH only ...

Страница 78: ...8 Technical specifications 78 ...

Страница 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...