3 - Description

17

Filters

A suction filter is fitted at the top of the tank and is indicated with red

hose tail.

In-line pressure filters can be fitted at each boom section as an option

(J).

Nozzle filters are fitted at each nozzle.

All filters should always be in use and their function checked regularly.

Pay attention to the correct combination of filter and mesh size (see

“Spray Technique” book).

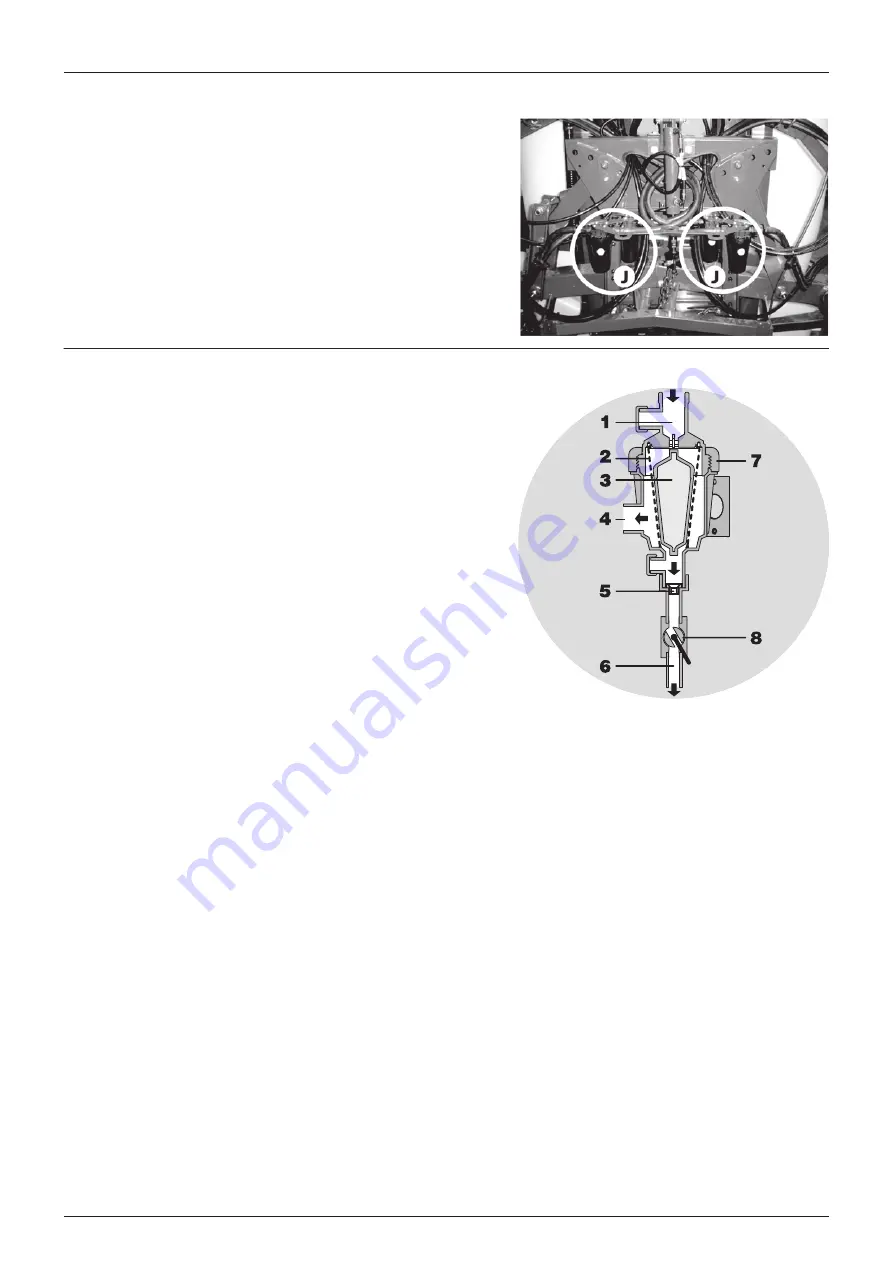

Self-cleaning filter

With the self-cleaning filter the impurities that exist in the spray liquid

will by-pass the filter and be recirculated back to the tank via the return

flow.

Function diagram

1.

From pump

2.

Double filter screen

3.

Guide cone

4.

To operating unit

5.

Exchangeable restrictor

6.

Return to tank

7.

Screw joint

8.

Ball valve

Ball valve (8) should normally be open, but may be closed in situations

where return flow is to be avoided, i.e. by flushing of spray lines without diluting the spray liquid in the main tank.

μ

ATTENTION! If the ball valve is closed, the self-cleaning function is inoperative!

Содержание MASTER PRO VHH

Страница 6: ...Table of Contents 6 ...

Страница 8: ...1 EC Declaration 8 ...

Страница 12: ...2 Safety notes 12 ...

Страница 50: ...5 Operation 50 ...

Страница 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Страница 70: ...7 Fault finding 70 ...

Страница 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Страница 77: ...8 Technical specifications 77 Boom hydraulic Y A Option for slanting B Option for single side folding VHH only ...

Страница 78: ...8 Technical specifications 78 ...

Страница 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...