A

WIRING

(continued on next page)

6

2.

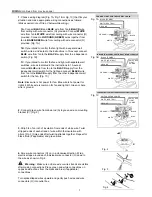

Remove pin (Q) and clip (R) from downrod (A). Slip downrod (A)

into housing yoke, align hole and re-install pin (Q) and clip (R).

Tighten downrod (A) set screws and then tighten nuts. Slide yoke

cover (G) down until it rests on top of motor housing (D). [Fig. 2]

Fig. 2

NORMAL OR ANGLE STYLE FAN MOUNTING

3.

Install ball end of downrod (A) into mounting bracket (C)

opening. Align slot in ball with tab in mounting bracket (C). [Fig. 3]

DANGER:

Failure to align slot in ball with tab may result in

serious injury or death.

Fig. 3

R

1.

Locate safety cable (U) at top of motor housing (D). Remove vice (V)

from safety cable (U) by loosening screw and nut. [Fig. 1A] Insert

downrod (A) through canopy (B), canopy cover (Y) and yoke cover (G).

[

Note:

Canopy cover (Y) must be turned with the shiny side

toward

the

motor housing (D)]. Thread wires from motor housing (D) through

downrod (A). [Fig. 1B] Thread wires and safety cable (U) from motor

housing (D) through downrod (A).

*Helpful Hint:

Downrod style mounting is best suited for ceilings 8 ft.

(2.44 m) high or higher. For taller ceilings you may want to use a

longer downrod (not included) than the one supplied. Angle style

mounting is best suited for angled or vaulted ceilings. Longer downrods

are sometimes necessary to ensure proper blade clearance.

Ball

G

D

WARNING:

To reduce the risk of fire, electrical shock, or

personal injury, wire connectors provided with this fan are designed to

accept only one 12 gauge house wire and two lead wires from the fan. If

your house wire is larger than 12 gauge or there is more than one house

wire to connect to the two fan lead wires, consult an electrician for the

proper size wire connectors to use.

CAUTION:

Be sure wiring box is properly grounded and that a

ground (green or bare) wire is present.

Warning:

If house wires are different colors than referred to in

following steps, stop immediately. A professional electrician is

recommended to determine wiring.

Q

Set

Screw

C

B

A

4.

Replace vice (V) on safety cable (U) and adjust safety cable (U)

length by loosening screw and nut on the safety cable vice (V) and

pulling on the safety cable (U). Adjust slack in cable to a hands length

and tighten vice (V) and nut securely. The loop at the end of the safety

cable (U) should just fit over the threads on the wood screw. [Fig. 4]

Test safety cable (U) by pulling on loose end with pliers. If the safety

cable (U) slips then vice (V) and nut must be set tighter.

Fig. 4

A

B

Wood

Screw

Screw

Loop

Nut

DANGER:

If using this fan in a DAMP location, this fan must be

connected to a supply circuit that is protected by a Ground Fault Circuit

Interrupter (GFCI) to reduce the risk of personal injury, electrical shock

or death.

5.

Find a secure attachment point (wood ceiling joist highly

recommended) and secure safety cable (U). It will be necessary to use

a heavy duty wood screw, washer and lock washer (not supplied) with

the safety cable (U) loop. [Fig. 5] Extra cable slack can be left in ceiling

area.

Fig. 5

B

Loop

Wood Joist

Wood Screw

and Washer

V

Screw

Nut

A

U

Fig. 1B

G

V

Nut

Screw

U

Fig. 1A

B

A

Y

U

V