Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

11

Turn the engine off, disconnect the spark plug wire and ensure rotor has completely stopped. Inspect

and sharpen or replace knives and/or anvil as required. Ensure correct clearances between knives and

anvil

The chipper starts making unusual noise, the cutting rotor strikes a foreign object or the chipper starts to vibrate

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped, then inspect

for damage

Replace or repair any damaged parts

Check for and tighten any loose parts

Do NOT

attempt to repair the chipper unless you are competent to do so

The chipper stalls when material is being fed

Auto Feed Control is not working

Check that AFC is on

Check the Autotrip setting is not at setting 0 or 20 (manual mode)

If AFC is not working, contact Hansa

The feed roller is not turning

Engine is not running at full throttle

Increase the engine throttle to max RPM

The feed roller is running too fast/slow

Hydraulic pump belt loose/broken

Tension/replace belt

Maintenance & service

Knife re-sharpening and knife replacement

How do I know that the knives need re-sharpening?

Chipper is vibrating excessively when processing material

Chipper is making more noise than usual when processing material

Rotor RPM is dropping more quickly than usual

Material comes out in long strips

How to re-sharpen the knives:

If you don’t have a surface grinder or are unsure how to re

-sharpen the knives, contact a professional saw doctor or Hansa to

arrange re-sharpening.

Tools and materials required for re-sharpening (approx. 40 mins):

•

24 mm ring spanner

•

19 mm ring spanner

•

16 mm ring spanner

•

14 mm Allen key

•

Torque wrench with a 24 mm socket and 16mm crows-foot wrench

•

A stick magnet (optional)

•

Surface grinder

•

Coolant

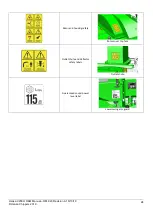

WARNING! Do NOT

open the housing unless the engine and cutting rotor have completely stopped.

WARNING!

Always ensure personal protective equipment (such as gloves and safety glasses) are used when servicing,

repairing, or conducting maintenance on your chipper. During maintenance or repair, ensure measures have been

taken to prevent unauthorised starting of your machine.

WARNING!

Do NOT

operate your chipper with blunt knives.

Blunt knives will cause excessive vibration

Blunt knives result in damage to the chipper

WARNING!

Be careful when working around the sharp knives. Be aware that even though the engine is switched off,

the cutting means can still move.