15 / 48

Hakki Pilke 55 Pro

Translation

Version 3-2022

3.2.3.

Electrical drive

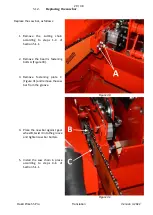

An electrically powered machine operates with a

21.3 kW motor. The fuse must be at least a 50 A

type C fuse. The electrical cable must be at least 5

x 10 mm², and the recommended maximum length

is 25 metres. In order to connect the cable, move

protective cover B of socket A (63 A power socket)

and the multiplier gear and secure it into a position

where it covers the multiplier gear.

In an electrically powered machine, the “control”

power cable for the electric controls is connected

to the three-pin socket on the side of the machine

(Figure 14a, upper). The cooler’s 12 V cable is

connected to the lower three-pin socket (Figure

14a, lower).

The electrically powered machine is turned on

with the green button of the remote starter,

located in the control panel in the front of the

machine (Figure 14). The starter itself is located

behind a protective sheet metal cover below the

remote starter. The starter features an automatic

fuse and a thermal relay for the electric motor. The

thermal relay can be reset by pressing the red stop

button on the starter at the front of the machine.

If the electric motor rotates in the wrong direction

(i.e. the machine makes an abnormal noise and the

hydraulic functions are inoperable), the current

phase is incorrect. The phase may only be changed

by an authorised electrician.

Figure 14. Electrica

l machine’s starter.

Figure 13. The machine’s electrical drive

Figure 14a. Electrical connector of the electric control

device