507961-01G / 31-5000653

Page 53 of 57

Issue 2128

For proper furnace operation the minimum gas supply

pressure is 4.5” w.c and the maximum gas supply pressure

is 10.5” w.c for natural gas. The minimum gas supply

pressure is 10” w.c. and the maximum gas supply pressure

is 13” w.c. for LP/propane gas.

Manifold Pressure Measurement

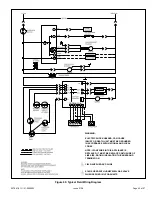

1. A manifold pressure post located on the gas valve

provides access to the manifold pressure. See Figure

71. Back out the 3/32 Hex screw one turn, connect a

piece of 5/16” tubing and connect to a manometer to

measure supply pressure.

2. Start unit and allow 5 minutes for unit to reach steady

state.

3. While waiting for the unit to stabilize, observe the

flame. Flame should be stable and should not lift from

burner. Natural gas should burn blue.

4. After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

NOTE:

Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Take care to re-

tighten the 3/32 Hex screw.

Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking

combustion. Take combustion sample beyond the flue

outlet and compare to the tables below. The maximum

carbon monoxide reading should not exceed 100 ppm.

High Altitude Information

NOTE:

In Canada, certification for installations at

elevations over 4500 feet (1371 m) is the jurisdiction of

local authorities.

Units may be installed at altitudes up to 4,500 ft. above

sea level without manifold adjustment. Units installed

at altitude of 4,501 - 10,000 feet (1371 to 3048 m) may

require a pressure switch change, which can be ordered

separately. Table 16 lists conversion kit and pressure

switch requirements at varying altitudes.

The combustion air pressure switch is factory-set and

requires no adjustment.

Other Unit Adjustments

Primary Limit

The primary limit is located on the heating compartment

vestibule panel. This limit is factory set and requires no

adjustment.

Flame Rollout Switches (Two)

These manually reset switches are located on the front of

the burner box.

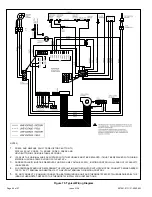

Pressure Switches

The pressure switches are located in the heating

compartment on the cold end header box. These switches

check for proper combustion air inducer operation before

allowing ignition trial. The switches are factory set and

must not be adjusted.

Temperature Rise

After the furnace has been started and supply and return

air temperatures have been allowed to stabilize, check

the temperature rise. If necessary, adjust the blower

speed to maintain the temperature rise within the range

shown on the unit nameplate. See Table 12 for allowable

heating speeds. Increase the blower speed to decrease

the temperature. Decrease the blower speed to increase

the temperature rise. Failure to adjust the temperature rise

may cause erratic limit operation.

Fan Control

The fan ON time of 30 seconds is not adjustable. The fan

OFF delay (amount of time that the blower operates after

the heat demand has been satisfied) is 120 seconds and

is not adjustable.

Thermostat Heat Anticipation

Set the heat anticipator setting (if adjustable) according to

the amp draw listed on the wiring diagram that is attached

to the unit.

Electrical

1. Check all wiring for loose connections.

2. Check for the correct voltage at the furnace (furnace

operating).

3. Check amp–draw on the blower motor.

Motor Nameplate__________Actual__________

Electronic Ignition

The integrated control has an added feature of an internal

Watchguard control. The feature serves as an automatic

reset device for integrated control lockout caused by

ignition failure. This type of lockout is usually due to low

gas line pressure. After one hour of continuous thermostat

demand for heat, the Watchguard will break and remake

thermostat demand to the furnace and automatically reset

the integrated control to begin the ignition sequence.

Exhaust and Air Intake Pipe

1. Check exhaust and air intake connections for tightness

and to make sure there is no blockage.

2. Is pressure switch closed? Obstructed exhaust pipe

will cause unit to shut off at pressure switch. Check

termination for blockages.

3. Obstructed pipe or termination may cause rollout

switches to open. Reset manual flame rollout switches

on burner box assembly if necessary.