58

FlexFit Pro

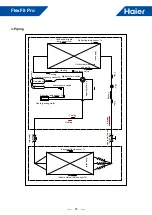

5. Installation

ENGLISH

SE

C

TION A

1.1

Step - 1.1

If attaching the supplied drain elbow to the outdoor unit,

do so prior to attaching the refrigerant lines and wiring.

Step1.2

Step 1.1

Step 1 - Installation of the Outdoor Unit

Attaching Drain Elbow to Outdoor Unit

1.2

Step - 1.2

Remove the cover plate of the outdoor unit to expose the

terminal block connections.

Electrical Connections for the Outdoor Unit

Step 1.3

Step 1.4

1.3

Step - 1.3

Connect the wiring for both the power source and indoor

wiring.

Wire the system according to applicable national / local

codes.

Verify that the wiring connections for the indoor unit match

wire for wire.

(1-1, 2-2, 3-3, Gnd-Gnd). Failure to wire the system correctly

may lead to improper operation or component damage.

1.4

Step - 1.4

Replace the cover plate.

Step 2.2

Step 2.1

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

B

Outdoor unit

Indoor unit

Oil trap

CAUTION

Max. Elevation: A Max.

= 100ft / 30m (24k / 36k)

In case the height of A is more than

15ft / 5m, an oil trap should be

installed every 16-23ft /5-7m

Max. Length: B Max

= 165ft / 50m (24k / 36k)

●

●

●

Illustration 4

Step 2 - Connecting the Indoor Unit

Piping

The standard lineset length is 25ft. If the installation length is

different, adjust the refrigerant charge by 0.5oz/ft.for the

24k,36k,42k and 48k model. (Illustration 4)

outdoor unit valves.

chart.

2.1

Step - 2.1

Refrigerant piping connections at the indoor unit are made

utilizing flare joints. Follow standard practices for creating

pipe flares. When cutting and reaming the tubing, use caution

to prevent dirt or debris from entering the tubing. Remember

to place the nut on the pipe before creating the flare.

2.2

Step - 2.2

To join the lineset piping together, directly align the piping

connection.

*See indoor section A, B, or C for electrical connections.

ENGLISH

Hazard of Explosion! Never use an open flame to detect

refrigerant leaks.. Explosive conditions may occur. Use a leak

test solution or other approved methods for leak testing.

Failure to follow recommended safe leak test procedures

could result In death or serious injury or equipment or

property damage.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for pressure

testing. Do not use mixtures of a hydrogen containing

refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in

an explosion. Refrigerant used as a trace gas should only be

mixed with dry nitrogen for pressurizing units. Failure to

follow these recommendations could result in death or

serious injury or equipment or property damage.

3.1

Step - 3.1

Using a tank of nitrogen with attached regulator, charge the

system with 150 PSIG of dry nitrogen. Use adapter AD-87

(field supplied) to connect to the service valve. Check for

leaks at the flare fittings using soap bubbles or other

detection methods. If a leak is detected, repair and recheck.

If no leaks are detected, proceed to evacuate the system.

Step 3.1

Step 3.2

Illustration 5

Leak Test

System Evacuation

Step 3 - Leak Test and Evacuation

3.2

Step - 3.2

Attach a manifold gauge, micron gauge, and vacuum pump

(Illustration 5)

Evacuate the system to 350 microns.

Close the vacuum pump valve and check the micron

gauge. If the gauge rises above 500 microns in 60 seconds,

evacuation is incomplete or there is a leak in the system. If

the gauge does not rise above 500 microns in 60 seconds,

evacuation is complete.

Step 2.3

Table 1

Half union

Flare nut

Torque wrench

Spanner

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Pipe Diameter(

ǿ

)

Fastening torque

Liquid side6.35mm(1/4")

18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2")

55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8")

60 N.m/44.3Ft.lbs

2.3

Step - 2.3

standard wrench, and one torque wrench. See Table 1 for the

Содержание FlexFit Pro AL24LP2VHA

Страница 1: ...SYJS 04 2017REV B Edition 2017 04 FlexFit PRO ...

Страница 8: ...FlexFit Pro 6 ...

Страница 9: ......

Страница 10: ...AW24LP2VHA AW36LP2VHA ...

Страница 11: ......

Страница 12: ...10 ...

Страница 13: ...11 ...

Страница 14: ...12 ...

Страница 15: ...13 ...

Страница 16: ...14 ...

Страница 17: ...15 ...

Страница 18: ...16 ...

Страница 19: ...17 ...

Страница 20: ...18 ...

Страница 37: ...35 FlexFit Pro ...

Страница 53: ...49 FlexFit Pro Part 5 Outdoor Units 50 2 Dimensions 53 3 Piping 55 4 Wiring diagrams 55 5 Installation 58 ...

Страница 72: ...68 FlexFit Pro 3 Outdoor PCB PCB 0151800054B Power module 0150401824 ...

Страница 90: ...86 FlexFit Pro Fig 4 1 ...

Страница 91: ...87 FlexFit Pro Fig 4 2 ...

Страница 108: ...104 FlexFit Pro 7 Controller External View of Remote Controller 7 1 Remote Controller YR HBS01 ...

Страница 121: ...Haier Commercial Air Condition Web Http www haier com Haier reserves the right to make change without any notice ...