97.2-118.6N.m

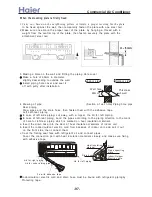

Connecting method (indoor unit)

Apply refrigerant oil at half union as large and flare nut.

To bend a pipe, give the roundness as possible not to crush

the pipe.

When connecting pipe, hold the pipe centre to centre then

screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands enter

the pipe.

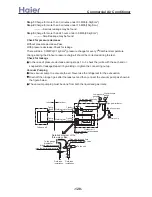

Piping connection

Forced fastening without centering may

damage the threads and cause a gas

leakage.

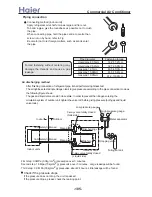

Pipe diameter

Fastening torque

Liquid pipe 6.35mm

Gas pipe 15.88mm

Liquid pipe 9.52mm

Gas pipe 19.05mm

14.2-17.2N.m

61.8-75.4N.m

32.7-39.9N.m

Gas pipe 12.7mm

49.5-60.3N.m

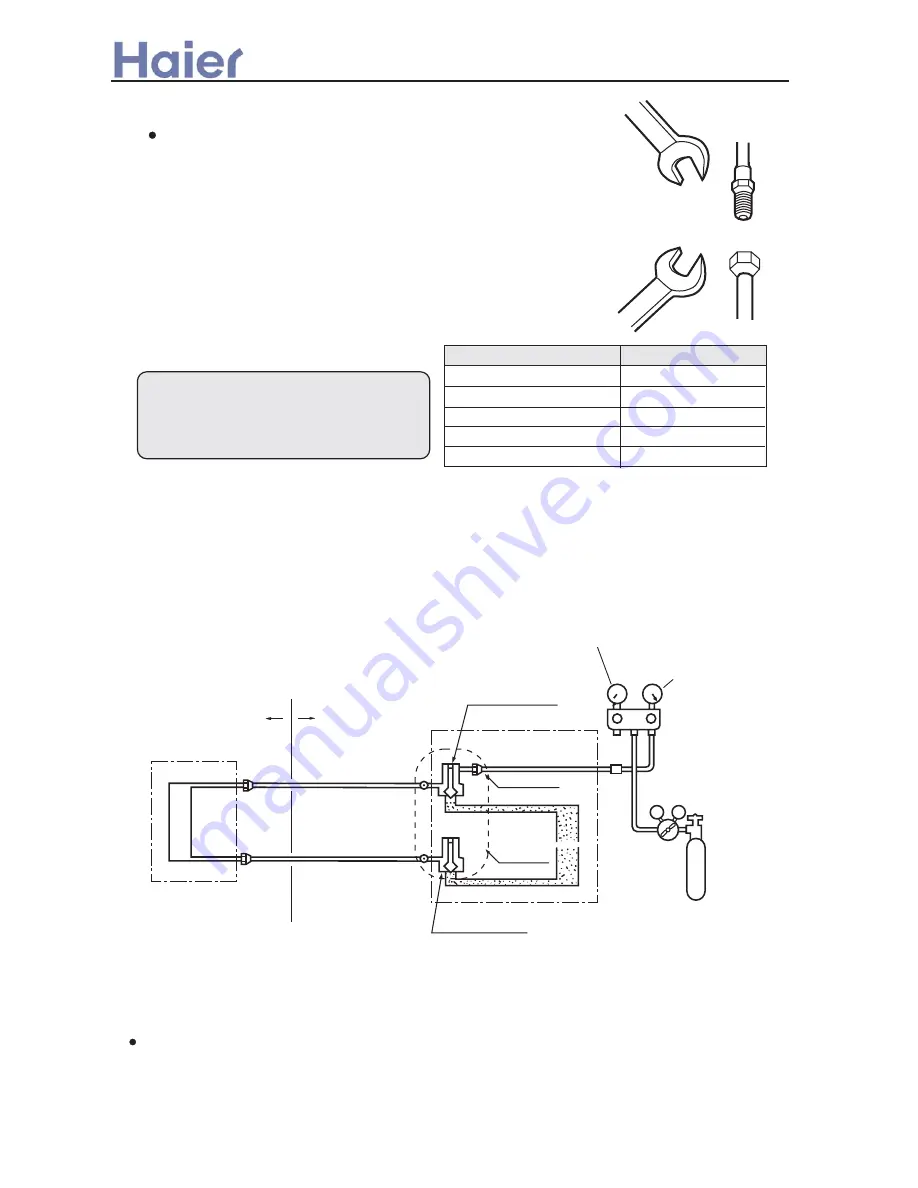

First step: 0.3MPa (3.0kg/cm2g) pressurize over 3 minutes.

Second step: 1.5Mpa (15kg/cm2g) pressurize over 3 minutes. Large leakage will be found.

Third step: 3.0 MPa (30kg/cm2g) pressurize about 24 hours. Little leakage will be found.

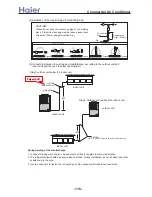

After finishing connection of refrigerant pipe, it shall perform air tightness test.

The air tightness test adopts nitrogen tank to give pressure according to the pipe connection mode as

the following figure shown.

The gas and liquid valve are all in close state. In order to prevent the nitrogen entering the

circulation system of outdoor unit, tighten the valve rod before giving pressure (both gas and liquid

valve rods).

Outdoor

Completely tightened

Completely tightened

Flare part

Outdoor units

Mainhole

Discharging valve

3-way valve totally closed

(Gas side)

Low pressure gauge

High pressure gauge

Meter separator

Dropping valve

2-way valve totally closed

(Liquid side)

Nitrogen tank

VLVH

Indoor units

Indoor

Flare part

Air discharging method

Check if the pressure drops

If the pressure does not drop, the unit is passed

If the pressure drops, please check the leaking point.

>a__WcU[S^ <[c >a`V[e[a`Wc

-105-

Содержание AB072XCBAA

Страница 21: ... a__WcU S c a V e a Wc AU84NXTBAA 66 33 1 23 4 43 33 61 2 3 160 2 15 3 52 21 ...

Страница 28: ... a__WcU S c a V e a Wc w y z x wt9 61 xt 98 96 816 yt5861 zt256 1 o MRWMHI p t9 61 2v xB r 2v xB r 2wzxB 28 ...

Страница 138: ... a__WcU S c a V e a Wc AU282XHBAA AU422XIBAA PCB printed diagram 138 ...

Страница 141: ... a__WcU S c a V e a Wc AU84NXTBAA PCB printed diagram 141 ...

Страница 144: ... a__WcU S c a V e a Wc AB AE AD units PCB printed diagram 144 ...

Страница 149: ... a__WcU S c a V e a Wc AF07 142XCBAA PCB printed diagram 149 ...

Страница 180: ...MEMO Commercial Air Conditioner ...