The transformer leads may be trimmed as desired for a neat job,

but be sure you do not cut any of them too short (particularly if

yours is the multi-voltage version, and any change to a different

supply voltage is likely). Cutting the leads too short for re-use

may void its warranty, if it is thought to be defective. Consult the

multi-voltage diagrams elsewhere in this manual fcr connec-

tions to the terminal strips which may differ from the stepby-

step instructions here.

Be sure all strands of each transformer lead are tinned and

soldered together before connection to a lug, so that there is no

possibility of a stray strand touching anything but the lug.

39

4 0

41

42

4 3

44

45

4 6

47

q

4 8

Select the remaining spade lug, and solder it to the black

transformer lead. Connect it to the PS left lug.

Select the .005 (502M) disc capacitor, and trim its leads to

l/2” or less. Wrap one lead around the shaft of the spade

lug which is connected to the PS left (inside) lug. Wrap

the other lead around the shaft of the spade lug con-

nected to the middle lug. Solder both leads. Be sure

there is adequate clearance between these connections,

and that the spade lugs are fully engaged.

Connect the black/white transformer lead to TS lug #5.

(S3). One of these wires was previously soldered to the

lower hole of this lug.

Twist together the two red transformer leads for

neatness, and connect one iead to DB lug #2. Connect

the other to DB lug #3.

Select the .Ol mfd (103M) disc capacitor, and trim its

leads to 3/4" Strip two 1/2” pieces of insulation from the

green wire, and slide one piece over each of the

capacitor leads. Connect one lead to DB lug #2. (S-2)

Connect the other lead to DB lug #3. (S-2) Make sure

both leads are securely soldered to each lug. Here you

could overlook a poor connection.

Connect the red/yellow transformer lead to the center

of the bare wire between the capacitor lugs. (S). Lowest

hum in the unit will be attained when all of the wires

which connect here are as close to the center of this wire

as possible.

Connect the

single

green wire from output terminal LB

to the center of the bare wire next to the transformer

lead. (S).

Connect the

single

green wire from RB to the center of

the bare wire on the other side of the transformer lead.

(S).

Connect the green wire from CL lug #3 between the two

input sockets to the center of the bare wire also. (S).

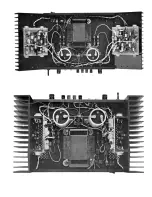

Select the output assembly modules (the two major

items in the kit). You will note that the only difference,

which identifies the left or the right module, is the posi-

tion of the thermal breaker, which is located between

one pair of output transistors on the heat sink rib. Before

connecting wires to these modules it is best that you take

the time to inspect the underside of the bottom row of

holes to make certain that connections already made to

some of these are well soldered. You will be making con-

nections from the top side to holes 3,5,6,7,8 and 10.

Make sure the proper connection point is clear at each of

these. If it is filled with solder, running the iron along the

underside will uncover the hole, and it may be cleared

with a wooden toothpick.

Now position the right module (with the breaker at the

front when the long bottom row of eyelets is next to the

chassis) with the circuit board

up,

against the side of the

chassis.

Wires will be connected to the holes from the top of the board,

and you must be sure they are soldered securely to the bright

circuit ‘pads’. Each hole is ‘plated through’ - it makes a connec-

tion to the other side of the board - and a good solder connec-

tion which heats the wire and the circuit pad properly will allow

solder to flow through the hole for a secure connection.

Even though the connecting wires are just long enough to make

the connections now, they will be rather long when the

amplifier is completed. That is why working room is limited.

Any wire which is to be connected to a hole on the board should

have a tight, tinned end. The wire supplied in the kit is already

tinned, so it would not normally require additional tinning

unless the tip is frayed. Melt a small amount of solder on the tip

of the iron so that it will make a good contact with both the

bared wire end, and the circuit pad as the wire is inserted into

the hole. Then add additional solder so that there is a smooth,

bright transition from the wire to the board as it cools undisturb-

ed. If you must use a great deal of heat on a connection, make

sure that you have not loosened any adjacent connections in the

process - especially wires from the back side of the board.

The holes #lo and #3 are very close to capacitors on the board.

Be sure heat does not damage these capacitors.

49 Prepare a 5 1/2" green wire. Connect one end to hole #lO

on the circuit board. (S). Make sure it

cannot

contact the

transistor mounting screw near the underside. Connect

the other end to FR lug # 2 (S).

50 Prepare a 6” white wire. Connect one end to hole #3. (S).

Connect the other end to FR lug #4. (s).

51 Select the green and white twisted pair from the output

terminals RR and RB. Connect the white wire to hole #5.

(S). Connect the green wire to hole # 7 (S).

52

q

Select the pair of white wires from RF. Connect the

shorter wire to hole #6. (S). Connect the other wire to

hole

(S).

53 Select 4 of the long sheet metal screws. Take care to see

that no wires are trapped in the process, while you tilt up

the module and fasten it to the end of the chassis. The

screws are inserted between the heat sink fins, and then

engage the chassis.

54

Select the green and white pair of wires from input

socket RS. Connect the white wire from the left to the

top (rear) hole #l. (S). Connect the green wire to hole #2.

(S). These wires should be soldered to the circuitry on the

underside of the board, although they are connected

from the top side of the board, assuring a good connec-

tion. These wires will be specifically positioned later,

9

though they now seem long.