Wiring the Kit

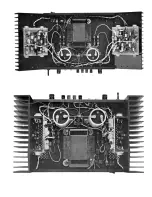

If any components are unfamiliar to you, checking the pic-

torial diagram should quickly identify them. Or, the quantities,

and the process of elimination as you check the parts list, will

help. The pictorial diagram is necessarily distorted to some ex-

tent for clarity, so that you can trace every wire in a single

overall view for verification as you work. You may wish to

check off on the diagram as you solder each location.

To “prepare” a wire means to cut the designated length from

the coil of that color, and strip about 1/4" of insulation from each

end. The wire supplied in the kit is #18, so you can set adjustable

wire-strippers accordingly. The transformer leads are #16 or

#18 and the line cord is #16. Be careful that you do not nick the

wire when you strip it (that can happen more easily if you do not

use wire strippers) for that weakens it. The wire supplied in this

kit is “bonded stranded,” which provides exceptional flexibility

with resistance to breakage for easier use, and it is pre-tinned.

Whenever a connection is to be soldered, the instructions will

so state, or indicate by the symbol (S). If more than one wire is to

be soldered to

the

same terminal, they will be indicated by (S-2),

(S3), etc. If soldering is not called for, other connections have

yet to be made to that terminal. They would be more difficult if

the connection was already soldered. Every connection in the

kit will be soldered when it is complete. After soldering a con-

nection, it is best to clip off any excess lead length to minimize

the possibility of a short circuit (as on switch lugs, where ter-

minals are very close together), and for a neat appearance.

Be sure that uninsulated wires cannot touch adjacent ter-

minals or the chassis metalwork.

The symbol (#) indicates a connection is to be made to that

point. When a lug number is specified without (#) it is simply a

locating reference.

When the instructions call for twisting two or three wires

together, the length of wire indicated anticipates a fairly tight,

uniform twist by hand, of three full turns every two inches. If

you find the wires too short, loosening the twist will gain some

needed length.

Handle the circuit boards carefully. They represent a major

part of the kit cost. Stand-up components, such as transistors,

should be checked when you install the module, to be sure all

leads are separated.

All of the active circuitry is contained on the PC-19 board,

which has been carefully tested to assure that it meets every

specification. Only the interconnection of power supply

elements is left to the builder. Take the time to be accurate and

neat, and you can be sure that your completed amplifier will

meet the performance of a factory assembled unit, and can con-

tinue to perform properly for years to come. Check your work,

and make sure the entire step has been completed before plac-

ing a check mark in the space provided, and continuing on to

the next step.

KEP nuts have been supplied as a convenience. These have

lockwashers attached, and the lockwasher always goes onto the

screw first. If the sheet metal screws have hex heads, you may

find it easier to first start them with a regular screwdriver, to set

the thread, and then use the more convenient nut driver, if one

is available.

Mechanical Assembly

1 When you unpack your kit, you will find that the

transformer, large capacitors, and the output assemblies

have been temporarily fastened to the chassis for safe

shipment. Disengage these, and include this hardware

with the rest when you check off the components

against the parts list in the back of the manual. We

recommend this check-off to be sure you have

everything, and to enable you to identify any unfamiliar

items by comparing them with the pictorial diagram. An

egg carton is ideal for keeping hardware items

separated.

A “set” of hardware includes one screw and one KEP nut (with

its attached lockwasher). Always install the lockwasher side of

the nut first. If the size of the hardware is not specified, use the #6

size. The smallest size is #4 and #lO the largest. Always insert

the screw from the outside of the chassis.

It will simplify matters if you first separate the #4 nuts from the

#6 nuts, which have the same outside dimensions. A #4 screw

will pass through a #6 nut, aiding identification.

2 Select the four rubber feet, four sets of # 6 hardware, and

the chassis. Insert each screw through a foot so that the

head is recessed, and install the feet on the outside at

each corner hole.

3 Select th e wo red output terminals. Install them in the

t

sequence shown below, in the two center holes LR and

RR marked

' +’

at the rear of the chassis. Before you fully

tighten the first nut, unscrew the cap to expose the hole

drilled through the threaded shaft. Connection of loud-

speaker wires will be easier if these holes are positioned

vertically. A nail through the hole will keep it positioned

while the hardware is tightened. Each connecting lug

should point downward before the last nut is secured. Be

sure both nuts on each terminal are

tight,

as they are dif-

ficult to reach when the amplifier is completed.

4 Select the two black output terminals and install them or

either side of the red ones, at LB and RR. Be sure the

shaft holes are vertical, the lugs point downward. and

each nut is tight.

6