Chapter 8 Maintenance

GK600 User Manual

- 246 -

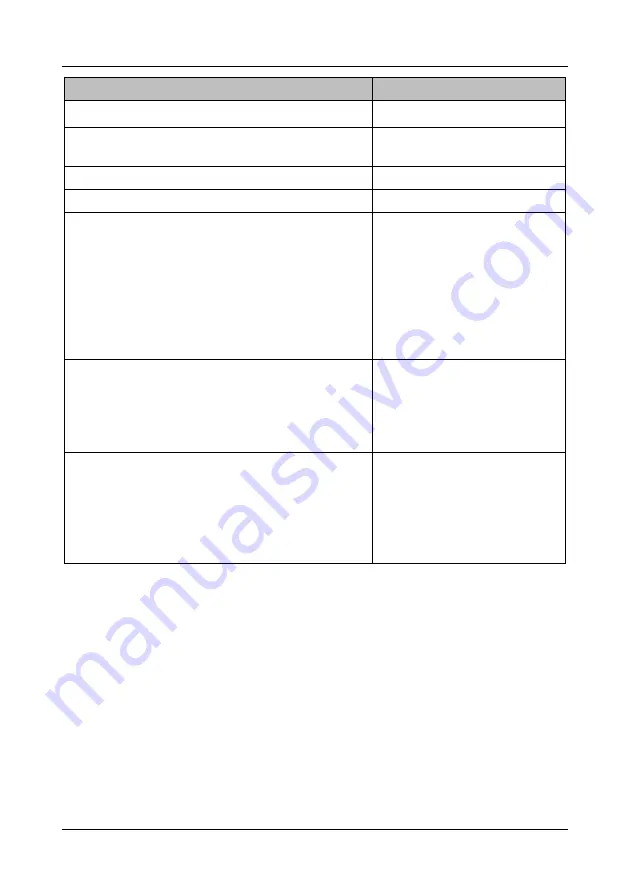

Inspection items

Measures

Check if drive mounting screws are loose

Tighten

Check if there are defect on power cables and control

cables

Replace the cables

Check if there is dust on circuit board

Clear it up

Check if air duct is blocked

Clear it up

Check if drive insulation is failed

Test the ground terminal with

500V megameter after all input

and output terminals are

short-circuited via conductors.

Ground test on individual

terminals is strictly prohibited

since this may cause damage to

inverter.

Check if motor insulation is failed

Remove input terminals U/V/W of

motor from drive and test the

motor

alone

with

500V

megameter. Failure to comply

may result in drive failure.

Check if the storage period of the drive is over two

years

Carry out power-on test, during

which, the voltage should be

boosted to rated value gradually

using a voltage regulator; be

sure to run at no load for more

than 5 hours.

8.3 Replacement of Vulnerable Parts

Vulnerable parts of drive include cooling fan, electrolytic capacitor, relay or contactor etc. The

service lives of these parts are subject to environment and working conditions. To maintain a

favorable operating environment is conducive to improving the service life of parts and

components; routine inspection and maintenance also contributes to effective improvement of

parts' service life. To prolong the service life of entire drive, the cooling fan, electrolytic

capacitor, relay or contactor and other vulnerable parts should be subjected to routine

inspection according to the table below. Please replace the abnormal parts (if any) in time.