2 - 6

GRUNDIG Service

Alignment

ACCORO 102

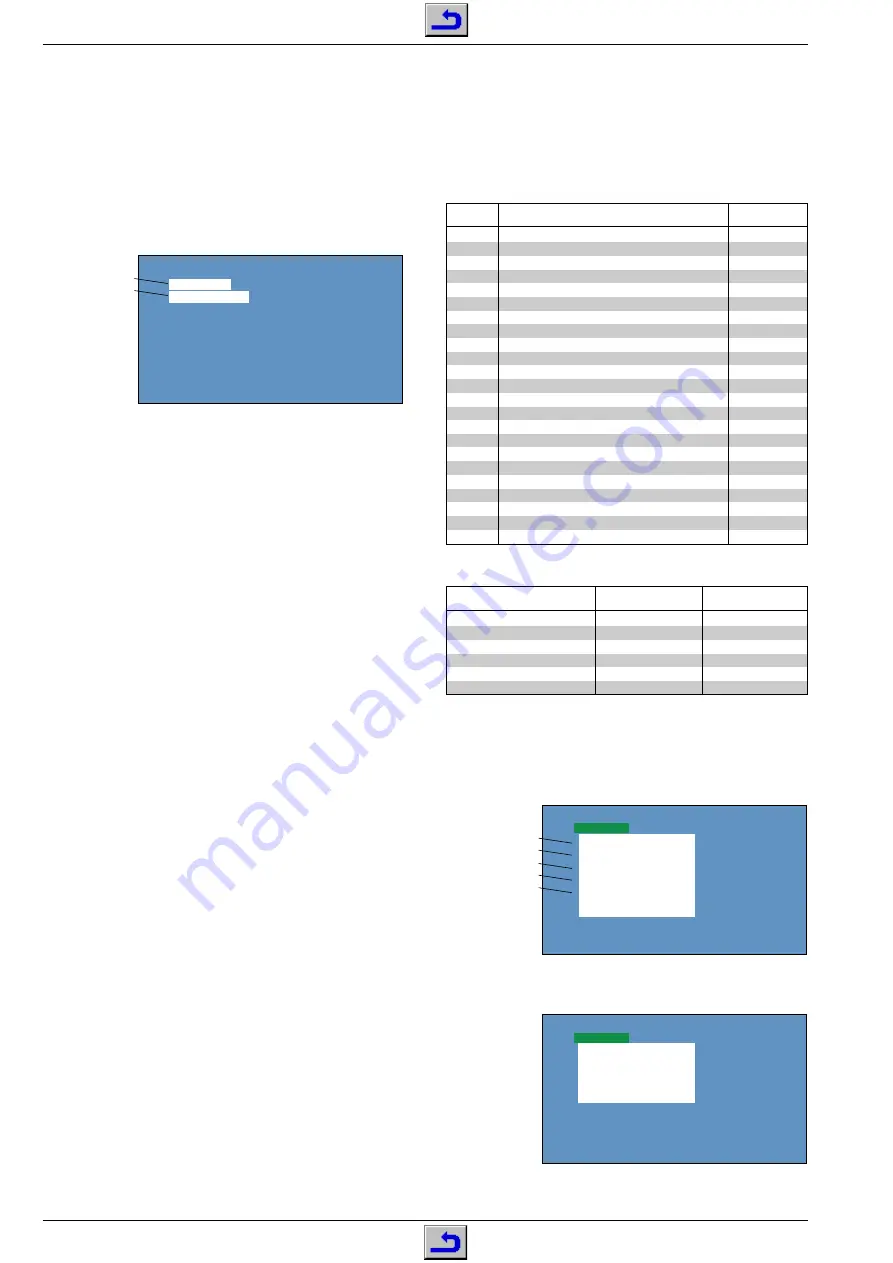

3. Test Patterns

–Activate the service mode (see Point 1.1).

–After every pressure on the

e

button appear one after the other the

test patterns red, green, blue, raster, white for PAL, and then for

NTSC.

4. Basic Settings

(PAL wide-screen zoom)

Display

Name

Refer. value

RCUT

R-cutoff (black level)

40H

GCUT

G-cutoff (black level)

40H

BCUT

B-cutoff (black levelt)

40H

RDRV

R-amplification (white level)

40H

BDRV

B-amplification (white level)

40H

BRTC

Basic brightness

80H

COLP

Basic colour saturation PAL

3DH

COLS

Basic colour saturation SECAM

3DH

SCNT

Basic contrast

08H

SBY

SECAM B-Y

01H

SRY

SECAM R-Y

07H

HPOS

Horizontal position

67H

VPOS

Vertical position

09H

HIT

Picture height

3FH *

VLIN

Vertical linearity

11H *

VSC

Vertical symmetry

0BH

VPS

Vertical operating point

1CH

WID

Picture width

1EH

PARA

East-West

11H

CNR

Corner correction

01H

TRAP

Trapezoid

20H

VFC

Vertical linearity (bottom)

0FH

VCEN

Vertical centre

6AH

*

Basic settings for picture formats

Picture format

HIT

VLIN

Wide-screen zoom

3FH

11H

Conventional 4:3

3FH

11H

Super live

4CH

0EH

Cinema zoom

62H

11H

Cinema zoom with subtitles

51H

11H

14:9

51H

11H

5. Selfcheck

–Activate the service mode (see Point 1.1).

–Press the

9

button.

The selfcheck settings appear on the picture screen.

SELFCHECK

2300xxxx

TIME

: 123456

POWER

: 00

BUS CONT :

OK

BLOCK

:

UV

V1 V2 V3

QV01

Software version

Operating hours

Overload-protection

Bus check

Input source

–Press the

9

button again.

The EPG/TEXT settings appear on the picture screen.

SELFCHECK

EPG/TEXT

QF01 xxx QF10 xxx

QF02 xxx QF03 xxx

QF04 xxx QF05 xxx

Alignment

1. Service Mode

1.1 Activating the service mode

–Press the

p

button.

–Press the

p

button again and keep it pressed while pressing the

MENU

button on the set.

–On the picture screen appear the alignment name and the alignment

value.

RCUT 0410H

40H 10000000B

Alignment Name

Alignment Value

1.2 Ending the service mode

–Press the standby button

A

or switch the set off.

1.3 Button functions

– Remote control buttons

1

R cutoff alignment

Indication: "RCUT"

2

G cutoff alignment

Indication: "GCUT"

3

B cutoff alignment

Indication: "BCUT"

4

Basic contrast

Indication: "SCNT"

5

Basic colour contrast

Indication: "COLP" with PAL

Indication: "COLS" with SECAM

Indication: "COLC" with NTSC

6

NTSC colour adjustment Indication: "TNTC"

9

Selfcheck (see point 5)

e

Test patterns PAL/NTSC (red / green/ blue/ raster/ white, see

Point 3).

ɾ

(yell.)

Convergence alignment (see Point 6).

C A L L

Initialisiation (see Point 2) / clear counter for service hours and

overload protection circuit (see point 5).

Info

Switch off pattern for SCREEN alignment.

– Direct control buttons (on the set)

zɦ

Select service function.

Ł ĵ

Change setting.

MENU

Display/exit alignment menu.

2. Initialization of the QA02

Attention: With this service function, all customer- and service-

specific software settings are cleared.

If the settings of the service functions should be displayable in the case

of service (see Point 4), it is recommended to note down these settings

in order to recover them after the replacement or the initialization of the

QA02.

The QA02 is to be initialized after replacement.

–Activate the service mode (see Point 1.1)

–Press the

CALL

button on the remote control, hold it down and press

the

ɦ

button on the set.

The screen turns black and the set switches temporarily to standby.

–Activate the service mode (see Point 1.1)

–Press the

CALL

button on the remote control, hold it down and press

the MENU button on the set.

Attention:

In this mode, carry out only the following settings,

otherwise the correct function of the set is not guaranteed.

–Use the

z

button to select the "OPT1" service function then use the

Ł ĵ

buttons to set the "7EH" value.

–Use the

z

button to select the "OPT0" service function then use the

Ł ĵ

buttons to set the "B0H" value.

–Check and correct the picture settings (see Points 6 and 7, alignment

no. 1, 3…6).