6

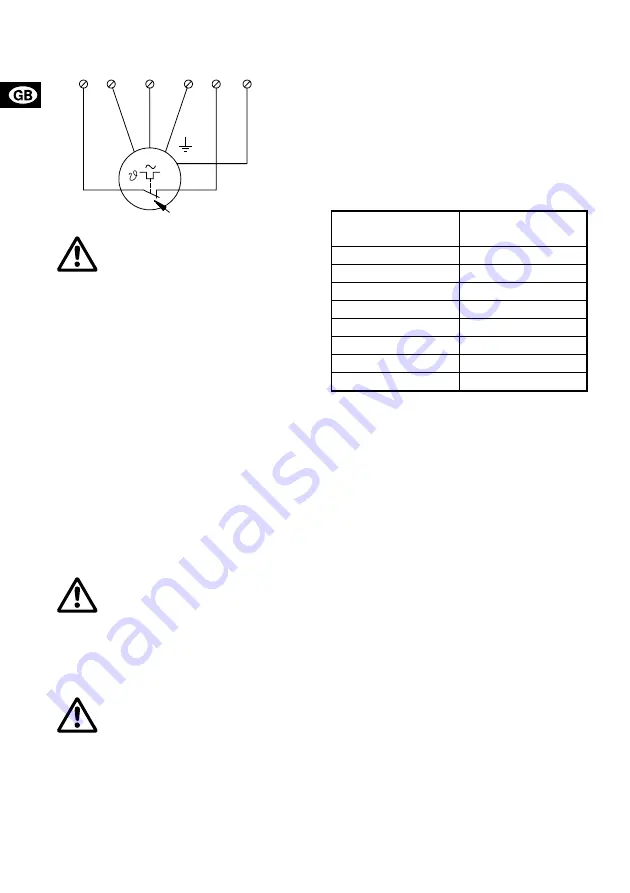

Fig. 1

6. Start-up

Do not start up the pump until the system has been

filled with liquid and vented. Make sure that the

pump is submerged in the liquid, open the isolating

valves, if fitted, and check the setting of the level

switches.

Note: The pump may, however, be started for a very

short period without being submerged for checking

of the direction of rotation.

6.1 Direction of rotation

Before starting up three-phase pumps, check the di-

rection of rotation. The direction of rotation should be

clockwise when viewed from above. When starting

up, the pump will jerk in the opposite direction to the

direction of rotation. If the direction of rotation is

wrong, interchange two of the three phases of the

electricity supply.

7. Maintenance and service

Before carrying out maintenance and service, make

sure that the pump has been thoroughly flushed with

clean water. Rinse the pump parts in water after dis-

mantling.

Pumps running normal operation should be in-

spected at least once a year. If the pumped liquid is

very muddy or sandy, inspect the pump at shorter in-

tervals.

When the pump is new or after replacement of the

shaft seals, check the oil level after one week of op-

eration.

For long and trouble-free operation of the pump the

following points should be checked regularly:

• Power consumption

• Oil level and oil condition

The oil becomes greyish white like milk if it con-

tains water. This may be the result of a defective

shaft seal. The oil should be replaced after 3000

hours of operation.

Use Shell Ondina 15 oil or similar type.

Note: Used oil must be disposed of in accordance

with local regulations.

The following table states how much oil the AP

pumps must have in the oil chamber:

Ex = explosion-proof.

• Cable entry

Make sure that the cable entry is watertight and

that the cables are not bent sharply and/or

pinched.

• Pump parts

Check the impeller, pump housing, neck ring, etc.

for possible wear. Replace defective parts.

• Ball bearings

Check the shaft for noisy or heavy operation (turn

the shaft by hand). Replace defective ball bear-

ings.

A general overhaul of the pump is usually required

in case of defective ball bearings or poor motor

function. This work must be carried out by the

manufacturer or a competent workshop.

7.1 Contaminated pumps

Note: If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be classi-

fied as contaminated.

If GRUNDFOS is requested to service the pump,

GRUNDFOS must be contacted with details about

the pumped liquid, etc. before the pump is returned

for service. Otherwise GRUNDFOS can refuse to ac-

cept the pump for service.

Possible costs of returning the pump are paid by the

customer.

However, any application for service (no matter to

whom it may be made) must include details about

the pumped liquid if the pump has been used for liq-

uids which are injurious to health or toxic.

TM

0

0

1

618

0

693

The separate control box/motor starter

must not be installed in explosive environ-

ments.

Before starting work on the pump, make

sure that the electricity supply has been

switched off and that it cannot be acciden-

tally switched on. Furthermore, all rotating

parts must have stopped moving.

When unscrewing the inspection screw of

the oil chamber, please note that pressure

may have built up in the chamber. Do not

remove the screw until the pressure has

been fully relieved.

M

Max. 250V / 2.5 A

T1

U

V

W

T2

PE

Max. 250 V/2.5 A

Pump type

Quantity of oil in

oil chamber

AP70.80.09.3

0.80 l

AP70.80.09.3Ex

0.80 l

AP70.80.13.3

0.80 l

AP70.80.13.3Ex

0.80 l

AP70.80.19.3

1.20 l

AP70.80.19.3Ex

1.20 l

AP70.80.24.3

1.20 l

AP70.80.24.3Ex

1.20 l