004-109

MOUNTING THE BENCHMATE

The BenchMate locks onto the

Fixed Mounting Plate (I. #004-

557)

attached to the front edge

of your bench. This offers several

advantages. It allows you to

remove the BenchMate quickly,

without tools, and reinstall it just as

easily. Additionally, you can change

from the BenchMate to the GRS

jeweler’s bench pin using this

same plate.

First, decide on the placement

of the Fixed Mounting Plate (it’s

designed for most wooden jeweler’s

benches). The six countersunk holes

give you the option to mount the

plate higher, lower or parallel with

your bench using the 4 wood screws

provided (fig. 1). Drill a 1/16” to 3/32”

pilot hole for each screw. Note that the

mounting plate is tapered two ways.

It is the taper that locks the BenchMate

onto your bench. You must install the

Fixed Mounting Plate EXACTLY as shown

in fig. 1. If the edge of your bench

is not thick enough you have two options:

1. You can add an extra board to the

top or bottom of your bench to make

a combined 1 1/2” to 2” thick edge

or, 2. You can order an Optional

Mounting Adapter (H. #004-559)

that screws to the top surface of

your bench instead of the edge.

USING THE BENCHMATE

INSTALLATION:

Once the Fixed

Mounting Plate has been fastened to

the front edge of your bench, you’re

ready to use the BenchMate. With the

word “TOP” (shown in fig. 2) on top,

slide the BenchMate firmly over the

Fixed Mounting Plate and pull down

sharply to lock it into plate, see fig. 3.

IDEAL POSITION:

Fig. 5 shows

the BenchMate at an angle from the

workbench. This position is ideal to

adjust the height of the BenchMate

if your workbench is too tall -OR- if

a microscope is used. This angle is

accomplished by loosening the two

hex screws (part A in fig. 5). Next, line

up the center point of knob 1 (fig. 4)

with the top of the work surface

(B in fig. 5). Hold onto the tube of

the BenchMate and tighten the

hex screws (part A in fig. 5) until

the BenchMate is secure again.

JAWS: The clamping jaws have a

plastic insert in them to prevent marring

of the workpiece. These are replaceable,

Extra Plastic Jaw Inserts for BenchMate

Holder (L. #004-090 or #004-558 pkg.

of 10)

. You should never solder on

any piece that is held in directly by the

jaws or you will melt the plastic inserts.

Special soldering clamps are available

to go between the BenchMate jaws and

the work when soldering. To replace the

plastic inserts, unscrew knurled knob 3

(fig. 4) and remove the jaw assembly

from the tube. Using a small rod, push

out the plastic insert from the outside of

the jaw into the center. Repeat for other

side. Position new inserts into the holes by

gently twisting to get them started.

Re-insert the jaw assembly into the tube,

aligning the

Locating Pin (#002-769)

into the slot in the bottom of the tube

and tighten the knurled knob. As the jaw

assembly is pulled into the tube, it will

press the plastic jaw inserts into position.

BenchMate

®

Instructions for Installing and Using the GRS BenchMate

®

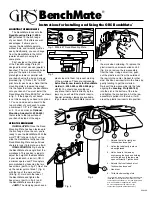

Fig. 1. #004-557 Fixed Mounting Plate

Fig. 2

1 - Adjusts the left to right pivot

friction when loosened *

2 - Holds the tube firmly in place

when tightened

3 - Holds items in the jaws by

unscrewing the knob and holding

onto the tube until the jaws are

open sufficiently. Tighten knob.

4 - Adjusts the front to back pivot

friction when loosened *

5 - Hand rest

6 - Third Hand mounting slots

*If you prefer a stiffer pivot, the black friction washer

(#004-089) can be removed from either pivot -OR-

remove the knob assembly (1 & 4) and replace with

3/8 - 24 hex bolts for a tighter pivot. NOTE:

Do not overtighten with the wrench or you

could crack the plastic washer (#004-091).

Fig. 4

Fig. 3

Fig. 5