Model G0923 (Mfd. Since 05/20)

-43-

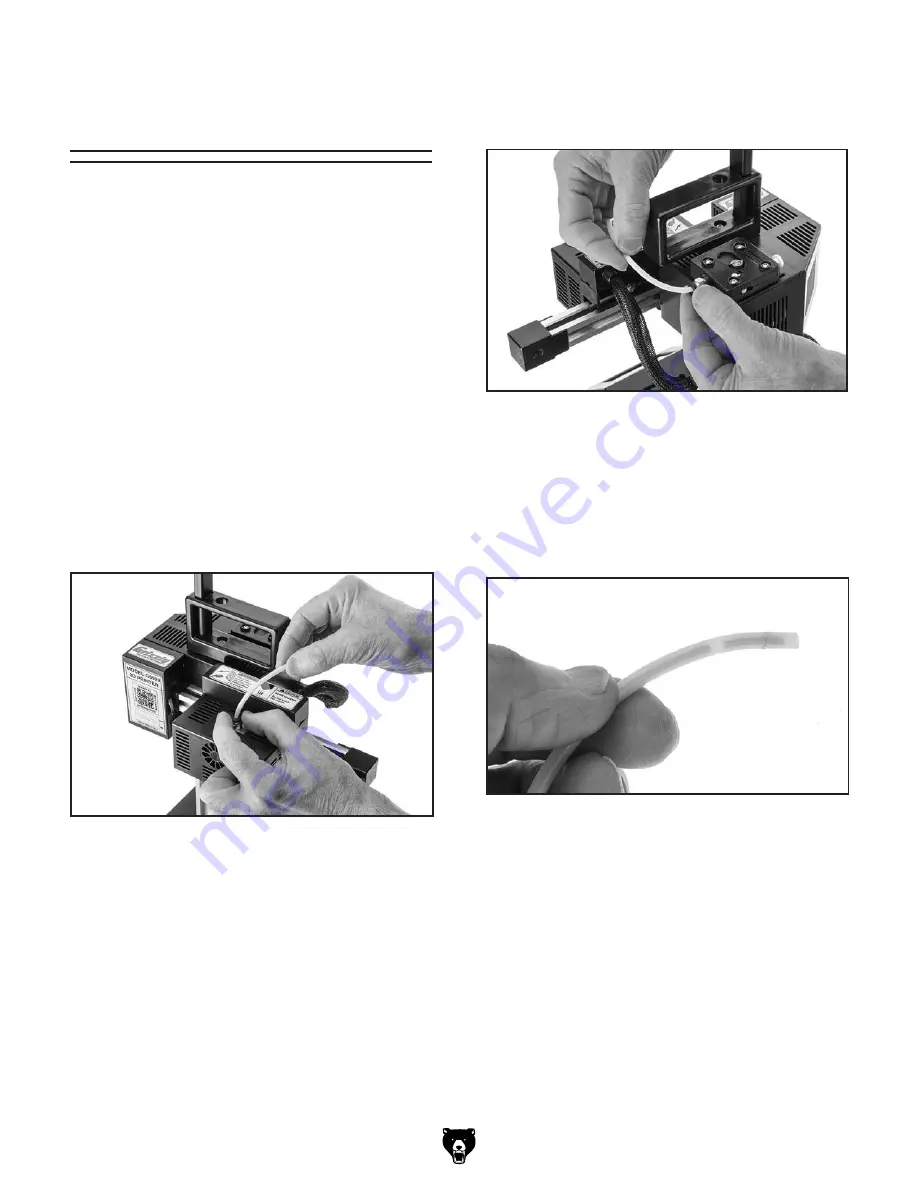

To clean feeder and Bowden tube:

1. Unload filament (see Loading/Changing

Filament on Page 29).

2. Remove Bowden tube from print head by

pressing down on tube coupler and pulling

firmly on Bowden tube (see

Figure 60).

Cleaning Feeder &

Bowden Tube

Figure 60. Removing Bowden tube from print

head.

Figure 61. Removing Bowden tube from feeder.

Figure 62. Cleaning Bowden tube.

4. Cut small piece of sponge or ball up piece of

tissue small enough to fit inside Bowden tube

(see

Figure 62).

5. Push material through Bowden tube with sec-

tion of filament (see

Figure 62).

6. Repeat Steps 4–5 until material leaves

Bowden tube clean.

7. Blow compressed air into feeder to remove

collected filament residue.

8. Connect Bowden tube to print head and

feeder by pressing down on tube coupler and

inserting Bowden tube.

Small particles of filament will get caught in the

feeder and Bowden tube. The Bowden tube can

be cleaned by running a small piece of material

through it to remove trapped residue. The feeder

can be cleaned by blowing air into it.

Tools Needed

Qty

Tissue or Sponge .............................................. 1

1.75mm Filament ............................... As Needed

Compressed Air ................................. As Needed

3. Remove Bowden tube from feeder by press-

ing down on tube coupler and pulling firmly

on Bowden tube (see

Figure 61).

Содержание G0923

Страница 56: ......