-28-

Model G0853 (Mfd. Since 07/18)

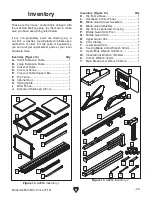

Assembly

2. Raise sliding table over machine frame (see

Figure 20A), position mounting plates over

mounting holes (see

Figure 20B), and lower

sliding table onto frame.

Figure 19. Location of mounting plates for

securing sliding table to machine frame.

Figure 20. Sliding table mounting plates

positioned over mounting holes in machine frame.

A

Sliding

Table

Mounting Plate

(1 of 3)

B

Mounting Holes

(1 of 3)

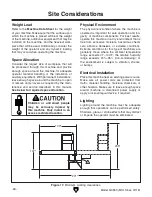

3. Press sliding table against parallelism adjust-

ment bolts at each end of machine frame

(see

Figure 21).

Note: These bolts are set at the factory and

do not need to be adjusted.

Figure 21. Sliding table parallelism adjustment

bolt (1 of 2).

Adjustment Bolt

(1 of 2)

Sliding Table

This machine must be fully assembled before it

can be operated. Before beginning the assembly

process, refer to

Needed for Setup and gather

all listed items.

The sliding table weighs nearly 400 pounds. It

must be lifted and carefully positioned onto the

machine frame during assembly. If you are using

a forklift to lift and place it, you'll need to use lifting

slings around the table to prevent scratching the

aluminum surface.

If you are not able to use the described forklift

method, the sliding table can be lifted into place

by four strong people—with one lifting from each

corner.

The only other part of the assembly that requires

additional help is installation of the extension

tables and blade guard arm. It takes approxi-

mately two hours to assemble the saw and make

the required adjustments to prepare the saw for

the test run.

To assemble sliding table saw:

1. Turn sliding table upside down and identify

(3) mounting plates, as shown in

Figure 19.