Model G0726 (Mfg. Since 7/11)

-39-

6. Set mill for the desired spindle speed, then

begin spindle rotation.

7. Select one of the three downfeed rates by

pulling knob of auto-downfeed rate selector

out, position selector over appropriate detent,

then release knob. Make sure pin is firmly

seated by attempting to move selector with-

out pulling knob out.

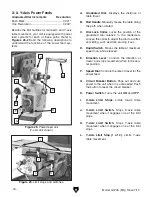

Note: Refer to the illustration in Figure 46

when selecting the downfeed rate.

8. Use coarse downfeed lever to lower spindle

slightly until you can pull clutch lever out to

the left and it locks in place, which will start

auto-downfeed spindle travel.

ALWAYS start spindle rotation before chang-

ing the auto-downfeed rate to avoid the risk

of gear damage.

Upper = 0.003 in./rev.

Middle = 0.0015 in./rev.

Lower = 0.008 in./rev.

(Rates given in inches of travel

per revolution of the spindle)

Figure 46. Positions of auto-downfeed rate

selector.

Spindle Brake

Your mill is equipped with a spindle brake that is

operated by moving the brake lever up or down to

quickly stop spindle rotation (see

Figure 47).

The spindle brake does not turn the motor

OFF.

ONLY use the spindle brake lever after you have

turned the spindle motor

OFF.

Figure 47. Spindle brake lever.

Spindle

Brake Lever

Содержание G0726

Страница 59: ...Model G0726 Mfg Since 7 11 57 READ ELECTRICAL SAFETY ON PAGE 56 Electrical Cabinet Wiring Diagram ...

Страница 76: ......

Страница 80: ......