-22-

Model G0718 (Mfd. Since 12/10)

Setup Overview

Operation Overview

The purpose of this overview is to provide the nov-

ice machine operator with a basic understanding

of how the machine is used during operation, so

the machine controls/components discussed later

in this manual are easier to understand.

Due to the generic nature of this overview, it is

not intended to be an instructional guide. To learn

more about specific operations, read this entire

manual, seek additional training from experienced

machine operators, and do additional research

outside of this manual by reading "how-to" books,

trade magazines, or websites.

The purpose of this overview is to provide the

machine operator a basic understanding of how

the machine is set up for most operations.

To set up the Model G0718, the operator does

the following:

1. Selects the specific cabinet door thickness

and hinge size.

2. Adjusts the hold-down clamps to the thick-

ness of the cabinet door.

3. Installs the correct boring head and bits for

the hinge type.

4. Adjusts the boring depth and setback position

for the size of hinge to be installed.

5. Adjusts the fence stops for the cabinet door

size and location of the hinge mounting

holes.

To complete a typical operation, the

operator does the following:

1. Positions the fence stops along the left and

right fences so they are both spaced the

same distance away from the center of the

cup bit, and then locks them in place.

2. Pivots one of the fence stops out of the way.

3. Places the cabinet door upside down on the

table, with the hinge side firmly and evenly

against the table fences, and one edge

against the remaining fence stop.

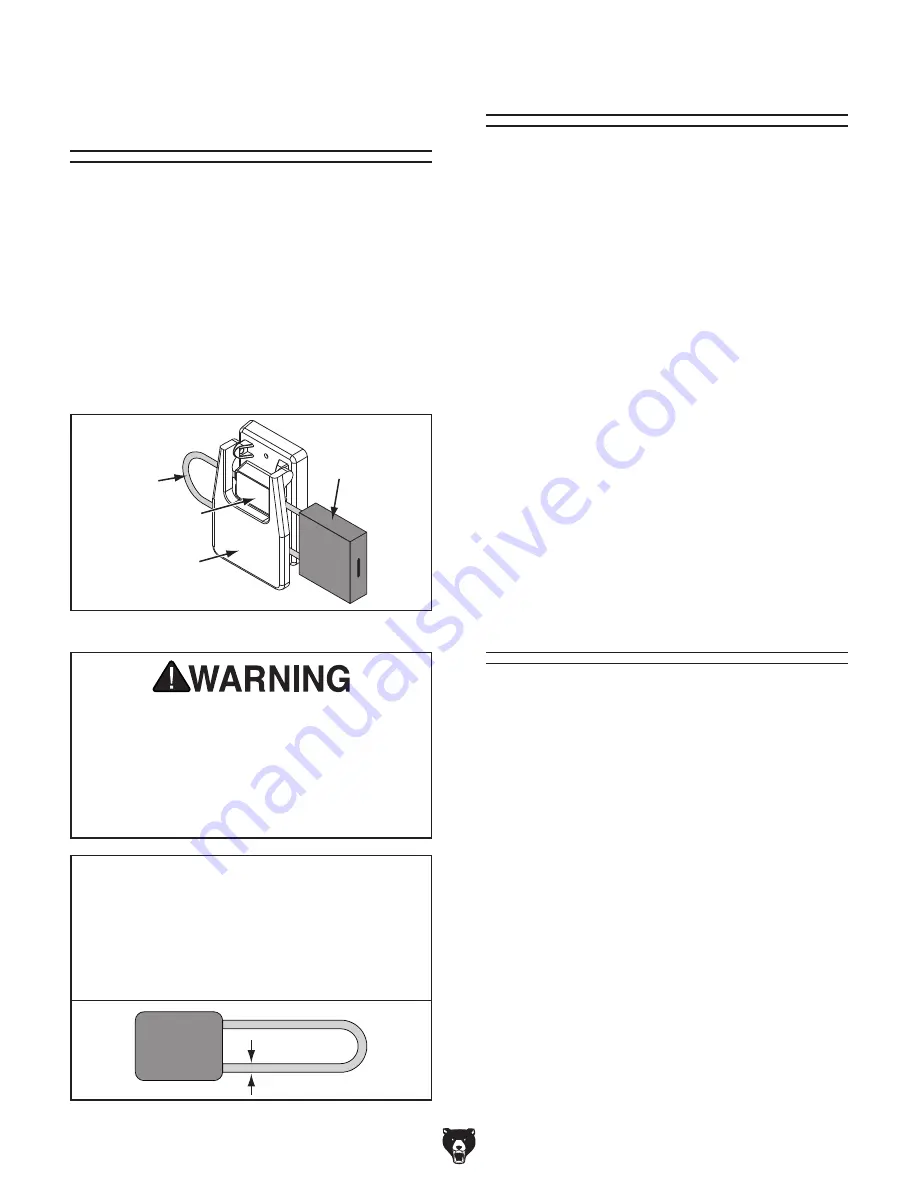

Disabling & Locking

Switch

Figure 25. Switch disabled by a padlock.

The switch can be disabled and locked by insert-

ing a padlock through the ON/START button, as

shown. Locking the switch in this manner can

prevent unauthorized operation of the machine,

which is especially important if the machine is not

stored inside an access-restricted building.

IMPORTANT: Locking the switch with a padlock

only restricts its function. It is not a substitute

for disconnecting power from the machine when

adjusting or servicing.

Shaft

Padlock

ON

/

START

Button

OFF

/

STOP

Paddle

Figure 26. Minimum lock shaft requirements.

NOTICE

The padlock shaft diameter is important to

the disabling function of the switch. With

any padlock used to lock the switch, test

the switch after installation to ensure that it

is properly disabled.

Children or untrained people can be

seriously injured by this machine. This

risk increases with unsupervised operation.

To help prevent unsupervised operation,

disable and lock the switch before leaving

machine unattended! Place key in a well-

hidden or secure location.

Содержание G0718

Страница 52: ......