-86-

G0677 24" Planer/Sander

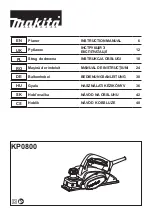

Main Wiring Panel & Controls Breakdown

8000 Series Parts

111

112

114

118

117

105

106

103

101

102

126

133

107

128

130

131

129

108

109

115

110

104

124

122

122

123

121

120

132

115-1

116

113

115-1

134

134-1

(440V)

134-2

REF

PART #

DESCRIPTION

REF

PART #

DESCRIPTION

101

PH29338101

ELECTRICAL CONTROL BOX

116

PH29338116

POWER WIRE TERMINAL

102

PH29338102

HINGE

117

PS51M

PHLP HD SCR M4-.7 X 30

103

PH29338103

DOOR

118

PH29338118

TERMINAL PLATE

104

PH29338104

BASE PLATE

120

PLW02

LOCK WASHER 1/4

105

PN05

HEX NUT 1/4-20

121

PB19

HEX BOLT 1/4-20 X 1/2

106

PLW02

LOCK WASHER 1/4

122

PH29338122

PU CONNECTOR 1/2"

107

PH29338107

CONTROL PANEL

123

PH29338123

PU CONNECTOR 1/4"

108

PS07M

PHLP HD SCR M4-.7 X 8

124

PH29338124

CABLE CONNECTOR 1"

109

PH29338109

CURRENT SENSOR

126

PH29338126A

DIGITAL AMP METER V2.02.06

110

PH29338110

TRANSFORMER

128

PH29338128

START SWITCH

111

PH29338111

CONTACTOR LC1-D40

129

PH29338129

STOP SWITCH

112

PH29338112

RELAY LR3D-3355 220V (30-40A)

130

PH29338130

POWER INDICATION LIGHT

113

PH29338113

FUSE TE10.3 X 38 & 500V/4A X 2

131

PH29338131

EMERGENCY STOP SWITCH

114

PH29338114

RELAY LR3D-086 220V (2.5-4A)

132

PH29338132

WIRE COLUMN

115

PH29338115

CONTACTOR LC1-D096 (WITH LOCK)

133

PH29338133

COMPUTER

115-1 PH29338115-1 CONTACTOR LC1-D096

REF

PART #

DESCRIPTION

134

P06778134

440V CONVERSION KIT

134-1 PH29338134

RELAY LR3D-3322 440V (17-25A)

134-2 PH29338135

RELAY LR3D-076 440V (1.6-2.5A)

440V Conversion Kit

440V Conversion Kit