Model IGX Make-Up Air

29

®

0.10 in. wg (0.02 kPa). for the upper pressure setting.

The needle indicates a negative building pressure.

During correct operation, the indicating needle will

remain between or near the setting needles.

External Signal

A VFD is controlled according to input from an external

2-10 VDC or 4-20 mA signal (by others).

A 2 VDC or 4 mA signal will send the fan to low speed.

The fan will go to maximum speed with a 10 VDC or

20 mA signal.

Variable Kitchen Control

A VFD is controlled by input from a speed control signal

from the kitchen hood. This unit allows automatic

adjustment of make-up air volumes based on varying

cooking loads.

Optional Duct Static Pressure Sensor

The controller will modulate the supply fan based upon

a comparison of the duct static pressure set point to

the actual duct static pressure level reported from the

sensor. Sensor shipped loose.

Optional Building Static Pressure Sensor

The controller will modulate the supply fan based upon

a comparison of the building static pressure set point

to the actual building static pressure level reported from

the sensor. Sensor shipped loose.

Control Voltage

Manufacturer’s standard control voltage is 24 VAC.

Control wire resistance must not exceed 0.75 ohms

(approximately 285 feet total (86.9 m) length for

14 gauge wire; 455 feet (138.7 m) total length for

12 gauge wire). If the resistance exceeds 0.75 ohms,

an industrial-style relay must be wired in place of the

remote switch. The relay must be rated for at least

5 amps and have a 24 VAC coil. Failure to comply with

these guidelines may cause motor starters to chatter or

not pull in, resulting in contactor failures and/or motor

failures.

Complete the

Supply Fan Pre-Start Checks and Start-

Up

sections in this IOM before proceeding.

For maintenance issues associated with a variable

frequency drive (VFD), consult the drive’s manual

supplied with the unit. The drives are programmed

at the factory and rarely need any adjustment during

installation and start-up. For some applications, the

drive may be located in the building or in the unit.

The VAV option is recommended when a building’s

exhaust volume may vary. This option enables the

make-up air volume to track the exhaust volume,

providing only the amount of make-up air required.

Control strategies include 2-speed and modulating

options. Before the unit is left in service, test the

variable air volume control system.

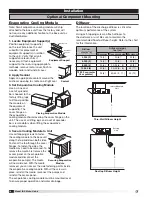

2-Speed Option

A VFD is used on a single speed motor to control air

volumes. The VFD is factory programmed for 2 speed

operation and can be switched to low or high speed

from a remote control panel. Turn the fan speed switch

on the remote control panel to each position and

confirm that the fan speed adjusts accordingly.

Modulating Options

Potentiometer Control

A VFD is controlled by input from a remote speed

selector (potentiometer). This option

allows easy manual adjustment of

make-up air volumes.

To test potentiometer operation,

turn the potentiometer to the two

extremes. Make sure the fan goes

to maximum and minimum speed.

When the potentiometer is at

minimum, the fan speed will be at its

minimum. When the potentiometer

is at maximum, the fan will be at its

maximum speed.

Building Pressure Control

A VFD is controlled according to input from a pressure

sensing device.

On the Photohelic

®

gauge, turn both

pressure knobs to the upper most

setting. The VAV system should go

to maximum speed. Set both knobs

at the lowest setting and the VAV

system should go to minimum speed.

Reset the correct pressure limits

before starting the unit.

Typical settings are 0.0 in. wg (0 kPa).

for the lower pressure setting and

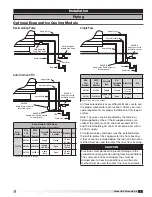

Start-Up: Indirect Gas-Fired Heating

Optional Features

EXHAUST

(OPTIONAL)

(OPTIONAL)

55

60

65

70

75

80

85

90

SUPPLY

HEAT

DIRTY FILTERS

MAIN VALVES

BLOWERS

Potentiometer

Control

70

65

75

80

85

90

60

55

(OPTIONAL)

BLOWER

DIRTY FIL TERS

MAIN V AL VES

EXHAUST

SUPPL Y

HEA T

(OPTIONAL)

PHOTOHELIC

Building Pressure

Control

Variable Air Volume (VAV)

Photohelic

®

Gauge

Pressure Indicating

Needle

Pressure Setting

Needles

Pressure Setting Knobs