Model IGX Make-Up Air

28

®

1. Check Electrical Connections

Tug test all internal electrical connections to ensure no

loose connections occurred during shipment.

2. Check Voltage

Before starting the unit, compare the supplied voltage,

hertz, and phase with the unit and motor(s) nameplate

information.

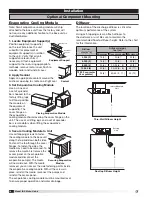

3. Check the Fan Rotation

Open the fan access door and run the fan momentarily

to determine the rotation. If the fan is rotating in the

wrong direction, the unit will move some air, but will

not perform as designed. Be sure to perform a visual

inspection to guarantee the correct fan rotation. Refer

to the arrows to indicate the proper direction. To reverse

the rotation of a three phase units, disconnect and lock-

out the power, then interchange any two motor leads. To

reverse the rotation of a single phase units, disconnect

and lock-out the power, then rewire the motor per the

manufacturer’s instructions.

Supply Fan

Start-Up

4. Check for Vibration

Check for unusual noise, vibration or overheating of the

bearings.

Excessive vibration may be experienced during the

initial start-up. Left unchecked, it can cause a multitude

of problems including structural and/or component

failure.

Generally, fan vibration and noise is transmitted to other

parts of the building by the ductwork. To minimize this

undesirable effect, heavy canvas duct connectors can

be used.

5. Motor Check

Measure the motor’s voltage, amps and RPM. Compare

to the specifications. Motor amps can be reduced

by lowering the fan RPM or increasing system static

pressure.

Additional starters and overloads may be provided in

the make-up air control center for optional external

exhaust fans. Exhaust fan motor voltage must match

unit nameplate voltage. Exhaust fan overloads must

be set to exhaust fan motor Full Load Amps (FLA).

Reference the exhaust fan manual for additional

information.

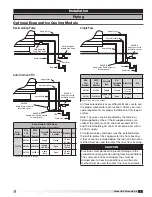

6. Air Volume Measurement

To ensure accuracy, the dampers are to be open when

measuring the air volume.

Measure the unit’s air volume and compare it with

it’s rated air volume. If the measured air volume is

incorrect, adjust the fan’s RPM by adjusting the variable

pitch sheave, if equipped, or replacing the sheave(s) if

necessary. Direct drive fan RPM must be adjusted by

changing VFD parameters. Consult factory for more

information.

The most accurate way to measure the air volume is by

using a pitot traverse method downstream of the fan.

Changing the air volume can significantly increase the

motor’s amps. If the air volume is changed, the motor

amp draw must be checked to prevent overloading the

motor.

7. Optional VFD

If unit is equipped with VFD, verify if VFD is provided

for a soft start/air balance in a constant volume

configuration or used as variable volume to vary the

supply fan speed. If unit is intended for variable volume,

reference

Sequence of Operation, Optional Variable Air

Volume

section in this IOM for more information.

Forward-Curved Fan Rotation

Mixed Flow Plenum Rotation

(Always counterclockwise as viewed from inlet)

Backward-Curved Plenum Rotation

(May be clockwise or counterclockwise as viewed from inlet)