114

Unit Installation

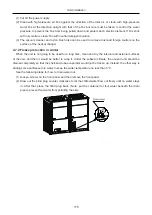

Even though water quality is under strict control, calcium oxide or other minerals will gradually

accumulate on the surface of the evaporator. Then, it will reduce the heat exchange efficiency of the

evaporator and consequently lead to poor performance of the unit.

Therefore, the pipe system should be cleaned periodically. Oxalic acid, acetic acid and formic acid can

be used as the organic

cleaning agent, but the strong chloracid is not allowed as it will corrode the copper

tube of the heat exchanger and then lead to water and refrigerant leakage.

(1) Preparation of materials and tools

Several bags of environmental friendly scale remover, or similar cleaning liquid.

(2) Cleaning instructions

1)

Estimate the required amount of scale remover in accordance with the system water volume and

severity of scailing.

2)

Add the scale remover to the water tank and the scale remover.

3)

Start through the contact the water pump every 10 minutes and spread the scale remover in water

more quickly and widely.

4)

After that, follow the steps below.

• Let the water pump run for another 1-2 hour(s).

• 1-2 hours later, change the cleaning solution to anti-rusting agent. Then, drain the water system

and check the water quality. If water is cloudy, then it indicates the cleaning effect is satisfactory.

• Open the water inlet to see if scale on the shell and tube has been removed. If not, clean the

shell and tube separately

again by the skilled serviceman and then rinse them. If there is still

sand, scale and other foreign matters at the bottom of

the shell and tube, let cleaning solution in

from the inlet pipe and then let the foul water out through the drain outlet.

• Fully charge the water system and let it run for another 1-2 hour

(s).

• Stop the unit to drain up waste solution. If impossible, drain it with making up water at the same

time until all waster solution has been drained out completely (at this time water is transparent

and PH is 7).

• Repeat steps last two steps above

.

• Clean or change the filters in the water system.

• See if the difference between the entering and leaving water temperature is improved.

NOTE

•

Although the cleaning agent is innocuous, but care also should be taken not to let it spill into eyes.

• The serviceman with injuries on the hand is not allowed to take this task.

Before and after cleaning, observe the running status of the unit, summarize the cleaning effect and

record the running parameters.

◆

Cleaning of the finned heat exchanger

In order to keep fins work efficiently, be sure there are no leaves, cotton wool, insects, and other

contaminants on the outer layer of fins, or they would lead to more energy consumption and high

discharge pressure. Generally, fins should be cleaned after the unit has run for 6-12 months, or more

frequently

when the environment is polluted more seriously.

Содержание LSQWRF35VM/NaA-M

Страница 1: ...Service Manual Change for life A series modular air cooled chiller heat pump T1 R410A 50Hz T1 R32 50Hz...

Страница 5: ...1 Product Product...

Страница 18: ...14 Unit Control Unit Control...

Страница 29: ...25 Unit Installation Unit Installation...

Страница 58: ...54 Unit Installation 3 5 7 Electric wiring digram 1 LSQWRF35VM NaA M...

Страница 59: ...55 Unit Installation 2 LSQWRF60VM NaA M LSQWRF65VM NaA M...

Страница 60: ...56 Unit Installation 3 LSQWRF35VM NhA M...

Страница 61: ...57 Unit Installation 4 LSQWRF60VM NhA M...

Страница 62: ...58 Unit Installation 5 LSQWRF130VM NhA M...

Страница 63: ...59 Unit Installation...

Страница 64: ...60 Unit Installation The electric wiring diagrams on the unit always prevail...

Страница 66: ...62 Test Operation Troubleshooting and Maintenance Test Operation Troubleshooting and Maintenance...