113

Unit Installation

4.7 Maintenance

4.7.1 Requirements for maintenance

The unit has undergone a series of strict tests prior to delivery to ensure qualified performance,

however, in order to keep reliable performance and extend its service life, the unit should be maintained

routinely and periodically by the qualified service personnel.

Routine maintenance items

Is there any unusual noise and vibration?

Is there any unusual noise and vibration for the compressor in operation? Is there any unusual smell?

Do the operating pressure, voltage and current keep normal? If not, figure out the cause and then

eliminate it?

Are all temperature sensors and pressure transducers installed securely?

Periodic maintenance items

Is any wiring loosened and insulated securely?

Does any electric element work reliably? If not, change it timely?

Does any throttling valve and control valve leaks? Can any valve be opened or closed flexibly? Is any

filter clogged?

Is the temperature setpoint proper?

Is there a large amount of condensate at the chilled water pipe or the condensate pipe? Is insulation

layer damaged?

◆

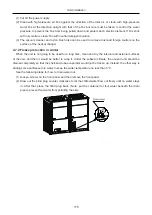

Requirements on water quality and cleaning

Industrial water used as chilled water produces little scale, but well or river water will bring much scale,

sand and other sediment which then would block up the chilled water flow and make the evaporator frozen

up. Therefore, it is necessary to filter or chemically soften water before it flows into the water system and

also take analysis to quality. Once it is found water quality is dissatisfactory, and then only industrial water

is available.

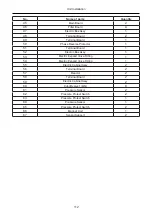

Water quality requirement

Items

Cold/hot water

Trend

Circulating

water

Makeup

water

Corrosion Scalelike

sediment

Basic

items

pH (25°C)

6.8-8.0

6.8-8.0

○

○

Electrical

conductivity

(25°C)

μs/cm

<400

<300

○

○

Cl-

mg (Cl-)/L

<50

<50

○

SO

4

2-

mg (SO

4

2-

)/L

<50

<50

○

Acid consumption

(pH4.8)

mg (CaCO

3

) /L

<50

<50

○

Total hardness

mg (CaCO

3

) /L

<70

<70

○

Other

items

Fe

mg (Fe) /L

<1.0

<0.3

○

○

S

2-

mg (S

2-

) /L

Undetectable

Undetectable

○

NH

4+

mg (NH

4+

)/L

<1.0

<0.3

○

SiO

2

mg (SiO

2

)/L

<30

<30

○

NOTE: “○” indicates possible corrosion or scaling.

Содержание LSQWRF35VM/NaA-M

Страница 1: ...Service Manual Change for life A series modular air cooled chiller heat pump T1 R410A 50Hz T1 R32 50Hz...

Страница 5: ...1 Product Product...

Страница 18: ...14 Unit Control Unit Control...

Страница 29: ...25 Unit Installation Unit Installation...

Страница 58: ...54 Unit Installation 3 5 7 Electric wiring digram 1 LSQWRF35VM NaA M...

Страница 59: ...55 Unit Installation 2 LSQWRF60VM NaA M LSQWRF65VM NaA M...

Страница 60: ...56 Unit Installation 3 LSQWRF35VM NhA M...

Страница 61: ...57 Unit Installation 4 LSQWRF60VM NhA M...

Страница 62: ...58 Unit Installation 5 LSQWRF130VM NhA M...

Страница 63: ...59 Unit Installation...

Страница 64: ...60 Unit Installation The electric wiring diagrams on the unit always prevail...

Страница 66: ...62 Test Operation Troubleshooting and Maintenance Test Operation Troubleshooting and Maintenance...