3-10

Basic Settings and Operations

3.7

Test Cutting

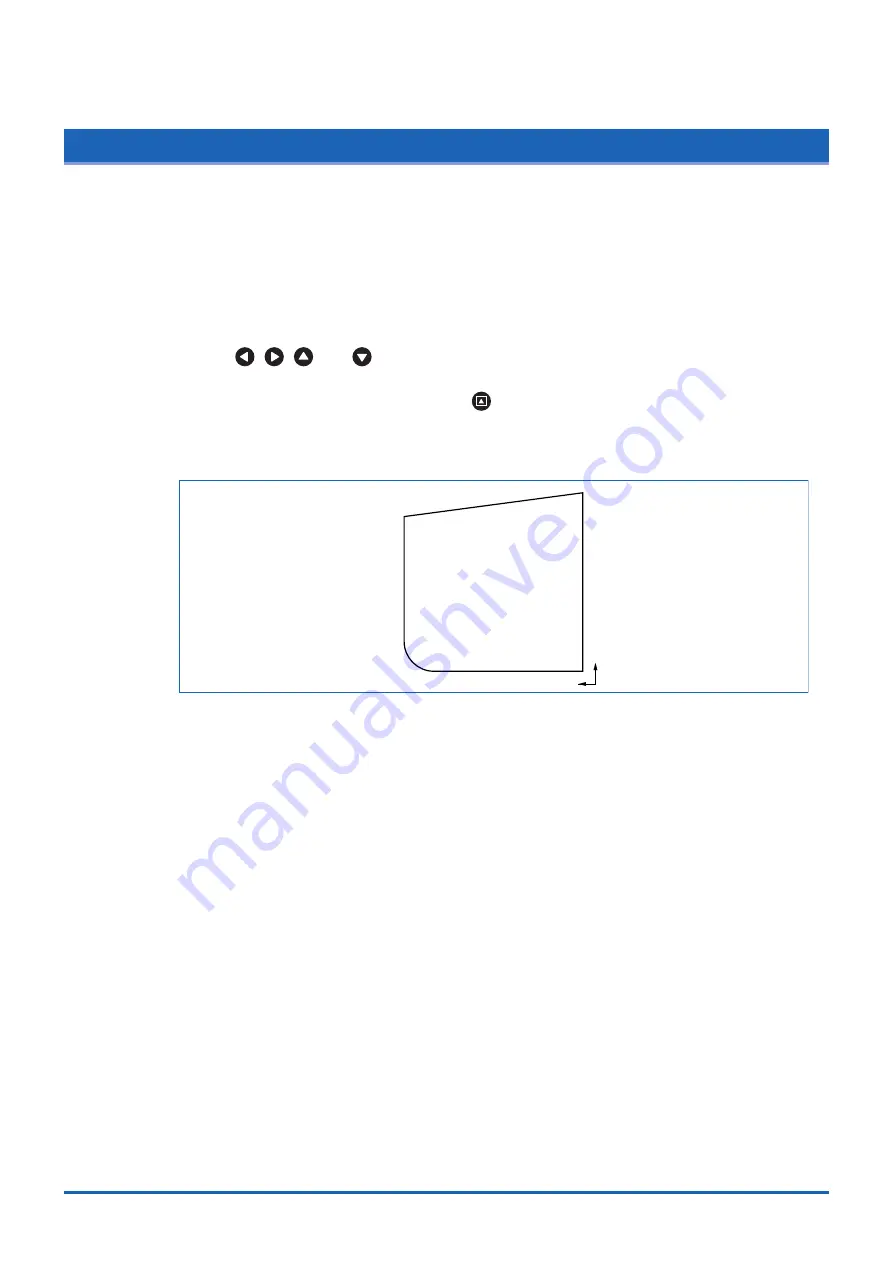

Test cutting can be performed after selecting the TOOL (cutter blade) and specifying the cutter-blade length,

OFFSET, FORCE, SPEED, and QUALITY settings to ensure that the selected cutting conditions actually

produce the desired cutting results. Check how far the blade cuts into the medium and how corners are being

cut; if the cutting results are not satisfactory, reset the cutting conditions and repeat the test cutting until the

optimal settings are achieved. If you perform test cutting while the cutter-pen conditions are being set, the

test cutting will be performed under the conditions being set.

(1) Load the medium for test cutting on the cutting plotter.

(2) Use the

,

,

, and

(POSITION) keys to move the pen carriage to the position for

test cutting.

(3) Switch to READY mode, and then press the

(TEST) key.

(4) Adjust the CUTTER OFFSET value to suit the type and thickness of the medium being used,

and fine-adjust the finish of each corner. Adjust the FORCE setting so that the medium is cut

through completely when the blade is extended to a suitable length.

X

Y

(5) Upon completion of fine adjustment, actual cutting data can be sent to the cutting plotter.

Содержание CE5000-120AP

Страница 1: ...CE5000 120AP USER S MANUAL MANUAL NO CE50AP UM 152 CUTTING PRO...

Страница 12: ...CHAPTER 1 Introduction 1 1 Checking the Accessories 1 2 Parts Names and Functions 1 3 Assembling the Stand...

Страница 103: ...A 4 Appendix Appendix C External Dimensions 1487 1020 1189 Units mm Dimensional accuracy 5 mm...