8.

Save all shipping materials. They must be reinstalled any time

washer is moved more than four feet.

IMPORTANT: Do not lift or transport unit from front

or without shipping materials installed. Refer to the

Maintenace section for proper instructions on rein-

stalling the shipping materials.

Connect Fill Hoses

WARNING

Under certain conditions, hydrogen gas may be pro-

duced in a hot water system that has not been used

for two weeks or more. HYDROGEN GAS IS EXPLO-

SIVE. If the hot water system has not been used for

such a period and before using the washer, turn on

all hot water faucets and let the water flow from each

for several minutes. This will release any accumula-

ted hydrogen gas. The gas is flammable. Do not

smoke or use an open flame during this time.

W029

Water Supply Requirements

Water supply faucets must fit standard 19 mm [3/4 inch] female

garden hose couplings. DO NOT USE SLIP-ON OR CLAMP-

ON CONNECTIONS.

NOTE: Water supply faucets should be readily accessi-

ble to permit turning them off when washer is not being

used.

Recommended cold water temperature is 10° to 24° Celsius [50°

to 75° Fahrenheit]. Recommended maximum hot water tempera-

ture is 51° Celsius [125° Fahrenheit]. Warm water is a mixture of

hot and cold water. Warm water temperature is dependent upon

the water temperature and the pressure of both the hot and cold

water supply lines.

WARNING

To prevent personal injury, avoid contact with inlet

water temperatures higher than 51° Celsius [125°

Fahrenheit] and hot surfaces.

W748

Maximum flow rate for all water temperatures is 9.46 liters per

minute [2.5 gallons per minute] ± 15%.

Water pressure must be a minimum of 138 to a maximum of 827

kPa [minimum of 1.4 bar to a maximum of 8.3 bar] static pres-

sure measured at the faucet.

NOTE: Water pressure under 138 kPa [20 pounds per

square inch] will cause an extended fill time in the

washer and may not properly flush out the detergent

dispenser.

The appliance is to be connected to the water mains using new

hose-sets and the old hose-sets should not be reused.

Turn on the water supply faucets and flush the lines for approxi-

mately two minutes to remove any foreign materials that could

clog the screens in the water mixing valve. This is especially im-

portant when installing your washer in a newly constructed or

renovated building. Build-up may have occurred during construc-

tion.

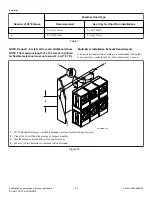

Model Numbers Ending in "06"

Connecting Hoses

To comply with water regulations, this washing machine must be

fitted with an approved 3/4 inch double check valve to both the

hot and cold supplies between shut off valve and fill hose. Refer

to

.

Maximum water flow rate to the dispenser is 10 liters per minute.

Installation Notice: Note that the Machines must be installed with

Double Check Valves at the Faucets which are not supplied.

1.

Insert rubber washers and filter screens (from accessories

bag) in water fill hose couplings (two hoses supplied with

washer). The filter screen must be facing outward.

NOTE: If using hoses with BSPP thread coupling, in-

sert filter screens into the BLACK colored hose cou-

plings and the rubber washers into the brass col-

ored hose couplings.

2.

Connect fill hose couplings with filter screens to water supply

faucets.

3.

Connect the other hose couplings to the hot and cold valve

connections at the rear of the washer.

NOTE: If using hoses with BSPP thread coupling,

connect the BLACK colored hose coupling end of

the fill hoses (with filter screens) to the water supply

faucets. Then connect end of hoses with the brass

colored hose couplings to the hot and cold water

mixing valve connections at rear of washer.

4.

Thread hose couplings onto valve connections finger tight.

Then turn 1/4 turn with pliers.

IMPORTANT: DO NOT cross thread or overtighten

couplings. This will cause them to leak.

5.

Turn water on and check for leaks.

6.

If leaks are found, retighten the hose couplings.

7.

Continue tightening and rechecking until no leaks are found.

Installation

©

Published by permission of the copyright owner -

DO NOT COPY or TRANSMIT

16

Part No. 805898ENR1