9

306-863

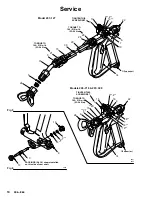

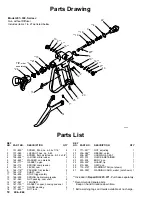

Service

Gun Repair (See Fig 5 except where noted)

NOTE: A repair kit is available for the standard guns

only. See pages 8 and 9. Use all the parts in the

kit for the best results.

NOTE: Parts included in the kit are marked with two as-

terisks, for example (16**), in the text and draw-

ings.

NOTE: Order parts separately as needed for the pole

gun (Model 207–127), being sure to replace the

packings, o-rings and glands at the same time.

1.

Relieve pressure. Disconnect the hose. Remove

the tip guard (24) and tip.

2.

Remove the trigger screws (1) and trigger (14).

3.

Remove the spring retainer (22), gasket (6**) and

spring (7).

4.

Remove the packing nut (13), packings

(4**,9**,16**) and cam shaft (10). See Fig 6.

5.

Model 207–127 only

: Remove the nozzle adapter

(31), washer (5), seat (21), gasket (15), extension

(30) and needle (20).

6.

Models 206–718 and 207–300 only

: Remove the

seat (21**) and gasket (15**). Remove the needle

(20) from the rear of the gun.

7.

Noting the number of full turns required to re-

move each one, remove the two nuts from the

needle: one each 18** and 19** for Models

206–718 and 207–300, and two 19** for Model

207–127.

8.

Clean all parts and inspect. Replace any worn or

damaged parts.

9.

Install a new gasket (15**) and seat (21**). Torque

the seat to 190–210 in–lb (23–24 N.m).

10. Model 207–127 only

: Install the nozzle adapter

(31).

11. Install the cam lever (8) and then the cam shaft

(10). Turn the shaft so the trigger clamps fit over

the flat ends of the shaft. See Fig 6.

12. Install the gland (16**), o–ring (4**), leather pack-

ings (9**) and packing nut (13) on each side of the

gun. See Fig 6.

13. Position the forks of the trigger clamps over the

cam shaft. Install the screws, tightening the inner

ones first as indicated in Fig 5.

14. Using the same number of turns noted in Step

4, install the adjusting nut (19**) and then the lock-

nut (18** or 19 as shown in Fig 5) on the needle.

15. Install the needle and spring. Now adjust the

needle as instructed to the left.