Troubleshooting

If the nozzle leaks, check the tightness of the valve seat

(21); it should be torqued to 190–210 in–lb (23–24 N.m).

See Fig 3. If the problem is not corrected, service the gun.

See page 6.

If fluid does not stop when the gun trigger is re-

leased, adjust the needle. See page 6. If the problem is

not corrected, check and/or replace the packings and

needle. See page 6.

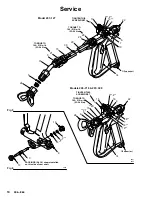

Service

Fig 4

0960

18

ADJUSTING NUT (19)

20

21

SAFETY

LATCH

5/16”

(8.1 mm)

19

ADJUSTING NUT

(19)

20

21

SAFETY

LATCH

5/16”

(8.1 mm)

Models 206–718 & 207–300

Model 207–127

5/16” (8.1 mm)

ACTUAL DISTANCE

PRESS NEEDLE (20) AGAINST

SEAT TO CHECK TRAVEL

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 6.

Adjusting the Needle

WARNING

Proper needle adjustment is essential to be sure

the safety latch makes the gun inoperative when

engaged. Improper adjustment may allow the gun

to be triggered, even with the safety latch engaged,

resulting in serious injury, including fluid injection

and splashing in the eyes or on the skin.

1.

Relieve pressure. Disconnect the fluid hose. Re-

move the spring retainer (22).

2.

Press the needle into the seat (21) with a finger.

With the safety latch disengaged, check the travel

of the gun trigger. It should be 5/16 in. (8.1 mm).

See Fig 4.

3.

Turn the first adjusting nut (19**) in or out as need-

ed to obtain the proper travel. Then lock it in place

with the locknut (18 or 19).

4.

Install the gasket (6) and retainer (22).

5.

Connect the fluid hose. Prime the system. Point

the gun into a grounded container and trigger and

release it. The fluid should stop flowing immediate-

ly. Now engage the safety latch and try to trigger

the gun. There should be no fluid flow. IF THE

GUN FAILS EITHER TEST, relieve pressure, dis-

connect the hose and readjust the needle.