5

306-863

Installation

System Requirements

WARNING

The equipment must have a bleed-type master air

valve (pneumatic pumps only) and a pressure drain

valve. These accessories help reduce the risk of

serious injury from fluid injection, splashing in the

eyes or on the skin, or moving parts, when

adjusting or repairing the pump or gun.

1.

The bleed-type master air valve relieves air

trapped between this valve and the pneumatic

pump after the air regulator is shut off. Trapped air

can cause the pump to cycle unexpectedly.

2.

The pressure drain valve assists in relieving fluid

pressure in the displacement pump, hose and gun;

triggering the gun to relieve pressure may not be

sufficient.

3.

Strain the fluid you are spraying if it contains

particles which could clog the spray tip.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking,

ground the pump and all other equipment

used or located in the spray area. Also

read FIRE OR EXPLOSION HAZARD on

page 2.

1.

Check your local electrical code for detailed

grounding instructions for your area and type of

equipment.

2.

Follow the grounding instructions provided in your

pump or sprayer manual. The gun obtains ground-

ing through connection to a properly grounded fluid

hose and pump or sprayer.

Installation

1.

Connect a grounded fluid hose to the gun inlet.

2.

With no tip installed, start the pump/sprayer. Flush

it according to the instructions supplied with it.

Prime the system with the fluid you are using.

3.

Follow the Pressure Relief Procedure, page 2.

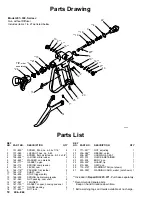

Fig 1

0957

1/2 npsm INLET

24

A

5

4.

With the gun safety latch engaged (see Fig 2), un-

screw the tip guard (21) and install the tip (A) and

gasket (5) in the nut of the tip guard. Screw the

assembly firmly onto the gun. Tighten with a

wrench. See Fig 1.

NOTE: Failure to install the tip gasket (5) will result in

leaking.

5.

Strain the fluid you are spraying if it contains par-

ticles which could clog the spray tip.