30

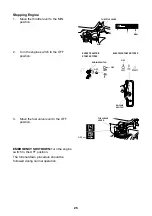

Tasks prior to spraying

CAUTION:

Before using this equipment with a chemical

mix, read and understand, the instructions

on the chemical label. The first time setup

procedure should be carried out as a water

test only prior to any chemical being applied to

the tank and applied.

Following the first time set up procedure being

followed, there are several important checks to

be carried out prior to starting spraying.

1. Inspect the sprayer to ensure there is no

damage or wear which could lead to injury,

further damage or reduce its performance.

2. Check all bolts and nuts to make sure they

are tight and secure.

3. Carry out scheduled lubrication.

4. Make sure the sprayer is securely attached

to the vehicle

5. Fill the flush water tank (where fitted) and

hand wash tank (where fitted) with an

appropriate amount of clean water.

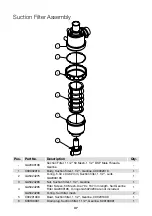

6. Clean all filters and nozzles.

7. Fill main tank with a quantity (approx 10%

of total tank volume) of fresh water.

8. Test the pump with clean water. To start

the pump, start the engine at the lowest

revs possible and then gradually increase

revs until the pump reaches your desired

operating speed.

CAUTION:

Do not exceed 540 RPM.

9. Check nozzle patterns for irregularities. If

there are irregularities, clean the nozzles

and replace. If the problem persists they

could be worn so remove and replace.

10. For optimal sprayer set-up, the operator

needs to be aware of the correct nozzle,

the correct speed at which to travel and

the appropriate rate per hectare to apply

the product. For this information, refer

to the chemical label, the supplier of the

product and the TeeJet catalogue.

11. Check all hoses and fittings for leaks or

damage.

12. Follow the chemical label and ensure that

you follow the specified mixing procedure

for addition of chemicals to main tank.

13. When mixing procedure has been

followed, fill main tank with appropriate

quantity of water required for task at hand.

14.

CAUTION:

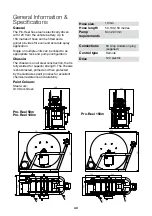

Traymount sprayers fitted with

manual hose reels should not exceed 160

psi maximum spraying pressure. If the unit

is fitted with a Pro Reel automatic rewind

hose reel the maximum operating pressure

is 300 psi.

WARNING:

When filling tanks with water, 1

litre of water will add 1 kg of weight. Some

chemicals weigh more than water, therefore

it is the operators responsibility to ensure the

loaded weight of the sprayer does not exceed

the towing and / or carrying capacity of the

vehicle.

15. You are now ready to start using the

sprayer

Operation

General

Before attempting to use your sprayer with

any chemicals, the application rate in litres

per hectare and the droplet spectrum need

to be considered. This information should be

readily available from your agronomist and by

referring to the chemical label.

NOTE:

Allow the pump to agitate the tank

mixture while filling. It is normal practice to

agitate the spray mixture before spraying. The

chemicals need to mix uniformly throughout

the spray mixture in order to achieve a correct

spray application. Agitation is primarily a

function of pump capacity, such that the larger

the pump the greater the amount of bypass

and hence the greater amount of agitation for

a given spraying application.

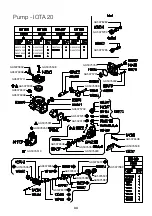

Connections

The following steps should be followed when

connecting to a power source:

1. Ensure that the battery is 12V DC

2. Connect the red connector to the positive

(+) terminal and the black connector to the

negative (-) terminal.

Calibration

All sprayers need to be calibrated and kept

in good condition. This will ensure that the