45

©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the

right to amend specifications without notice or obligation.

MAINTENANCE OPERATIONS COMPRESSOR

Compressor Oil Level Check - Oil / Filter Change

Please refer to section

Installation and Initial Set-Up

for location of level checking,

drain and filling features.

Drain oil and change the filter (with the compressor warm) in accordance with the Prima

SmartCAFS maintenance

manual.

Compressor Air Filter

Change the air filter in accordance with the Prima SmartCAFS maintenance manual.

Compressor Oil Separator Element

Change the element in accordance with the Prima SmartCAFS maintenance manual.

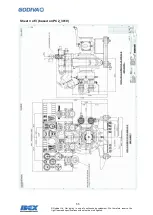

Compressor Drive Belt

Check and adjust belt tension, as required, in accordance with section

Installation and

Initial Set-Up

.

Change the drive belt at the recommended interval or if damage occurs.

To remove the belt, slacken the tensioner bolt and position the tensioner to allow belt

removal.

Fit the new belt ensuring that belt alignment and position on the pulleys is uniform.

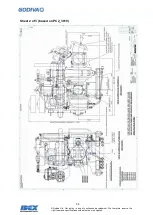

See section

Installation and Initial Set-Up, Compressor Drive Belt

for tension setting

detail.

MAINTENANCE OPERATIONS FOAMLOGIX

Strainer - Foam

Remove and clean the foam strainer screen(s) and flush as required. Please refer to the

appropriate

FoamLogix

Description, Installation and Operation manual - System

Plumbing Diagrams for location.

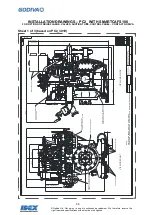

Calibration

Please refer to the appropriate model

FoamLogix

Description, Installation and

Operation manual to calibrate water flow and foam feedback characteristics.