18

Installation and maintenance instructions EASICOM 3 0020239562_04

7

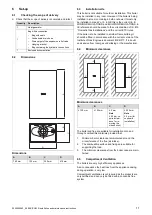

Installation

7.1

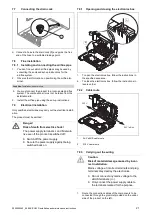

Preparing for installation

▶

Make sure that the existing gas meter is capable of

passing the rate of gas supply required.

▶

Consider the maximum heat output given in DHW mode.

▶

Install a system separator (to be provided on-site) directly

on the cold water connection for the combi boiler.

▶

Install the following components:

–

Draining cocks at the lowest points in the heating

installation (

→

current version of "BS 2879")

–

A stopcock on the cold water connection

–

A stopcock in the gas pipe

▶

Check that the volumetric capacity of the expansion ves-

sel is sufficient for the system volume.

▽

If the volume of the expansion vessel is insufficient

for the installation.

▶

Install an additional expansion vessel in the heat-

ing return, as close to the product as possible.

▶

Install a non-return flap at the product's outlet

(heating flow).

▶

Install the connection pipes such that they are free from

mechanical stress.

▶

If you use non-diffusion-tight plastic pipes in the heating

installation, ensure that no air gets into the heat gener-

ator circuit.

▶

Only solder connectors if the connectors are not yet

screwed to the service valves.

▶

Only bend connection pipes if they have not yet been

connected to the product.

▶

Flush the heating installation thoroughly before installing

the product.

▶

Check the leak-tightness of the gas valve assembly using

a pressure of

≤

11 kPa (110 mbar).

7.2

Descaling the water

Scale deposition increases as the water temperature in-

creases.

▶

Descale the water as required.

7.3

Check compliance with the local gas group

The product's combustion has been factory tested and is

preset for operation with the gas group indicated on the data

plate.

The product is only authorised to be operated with natural

gas.

▶

Check the information about the gas type indicated on

the data plate and compare this with the gas type avail-

able at the installation site.

Condition

: The product design

is not compatible

with the local gas group

▶

Do not start up the product.

Condition

: The product design

is compatible

with the local gas group

▶

Proceed as described below.

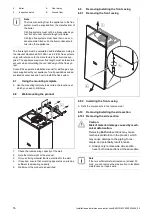

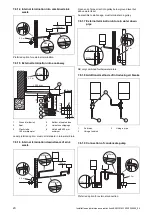

7.4

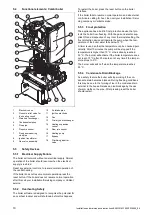

Gas and water connections

Note

Apply heat insulation to the water pipes to the

boiler outlet and to the installation.

1

2

3

4

5

1

Heating flow connec-

tion, G3/4

2

Domestic hot water

connection, G3/4

3

Gas connection, G1/2

4

Connection for the cold

water pipe, G3/4

5

Heating return connec-

tion, G3/4

1.

Connect the water and gas connections in accordance

with the applicable standards.

2.

Purge the gas pipe before start-up.

3.

Check whether the connections (

Page 29) are leak-

tight.

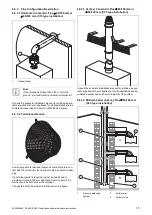

7.5

Connecting the drain pipework for the

expansion relief valve

1

▶

Ensure that the pipeline is visible.

▶

The pipe must have a continuous fall and be routed to a

position so that any discharge of water, possibly boiling,

or steam cannot create any danger to persons, damage

to property or external electrical components and wiring.

Содержание EASICOM 3 24c

Страница 1: ...en Installation and maintenance instructions EASICOM 3 24c 28c 0020239562_04 31 07 2020 ...

Страница 54: ......

Страница 55: ......