0020313973_01 Compact Installation and maintenance instructions

29

9.3

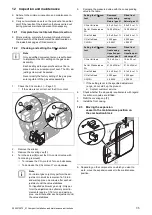

Filling the heating installation

Note

After each start-up, the product works at reduced

output when starting in order to facilitate the heat

transfer effect. This does not apply for check pro-

grammes and does not result in any loss of com-

fort for the end user. Status code

S.58

corres-

ponds to this phase. The display shows a tem-

perature of approx. 50 °C in this phase.

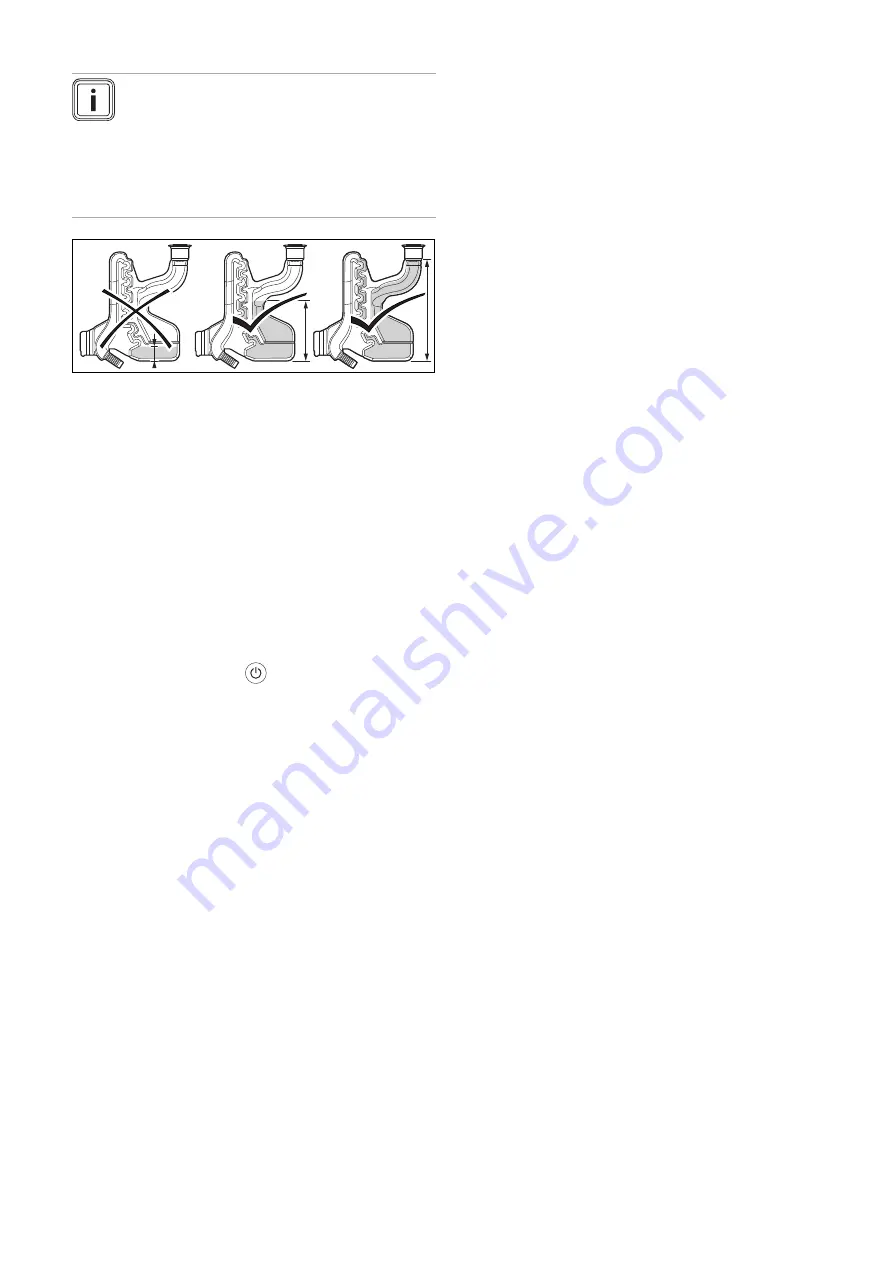

1.

Ensure that the condensate siphon has been filled cor-

rectly.

2.

Before filling the heating installation, ensure that it has

been flushed out sufficiently.

3.

Connect the filling/draining cock in the heating install-

ation to a heating water supply in accordance with the

relevant standards.

4.

Open all of the thermostatic radiator valves and, if re-

quired, the service valves.

5.

Open the heating water supply and the filling tap so

that the heating water flows into the heating installa-

tion.

◁

The heating circuit is automatically purged via the

hose that is connected to the pump.

Starting up the product

6.

Press the on/off button

.

◁

The display shows the basic display.

7.

Start check programme

P.08

. (

Check programmes (

◁

The product's heating circuit is automatically

purged via the hose that is connected to the pump.

8.

Purge the highest radiator until water flows out of the

purging valve without bubbles.

9.

Purge all other radiators until the entire heating installa-

tion has been completely filled with heating water.

10.

Close all purging valves.

11.

Fill with heating water until the required filling pressure

is reached.

–

0.10 to 0.14 MPa (1.00 to 1.40 bar)

▽

If the heating installation extends over several

storeys, higher filling pressures may be required to

avoid air entering the heating installation.

12.

Close the filling tap and the heating water supply.

13.

Check all of the connections and the entire circuit for

leaks.

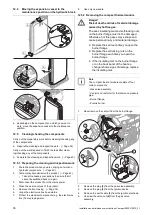

9.4

Purging the heating installation

1.

Start the check programme

P.00

. (

Check programmes (

◁

on

is shown in the display.

2.

Make sure that the filling pressure of the heating install-

ation does not fall below the minimum filling pressure.

– ≥

0.05 MPa (

≥

0.50 bar)

3.

Check whether the filling pressure of the heating in-

stallation is at least 0.02 MPa (0.2 bar) above the dia-

phragm expansion vessel's counter-pressure (P

system

≥

P

diaphragm expansion vessel

+ 0.02 MPa (0.2 bar)).

Result:

Filling pressure of the heating installation is too low

▶

Refill the heating installation.

4.

If there is still too much air in the heating installation

at the end of the check programme

P.00

, restart the

check programme.

9.5

Filling and purging the domestic hot water

system

1.

Open the cold-water isolation valve on the product.

2.

To fill the domestic hot water circuit, open all of the

domestic hot water tap fittings until water escapes.

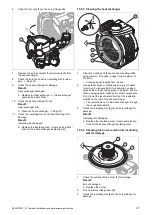

9.6

Check and gas setting

9.6.1

Checking the factory-set gas setting

▶

Check the information about the gas type indicated on

the data plate and compare this with the gas type avail-

able at the installation site.

Result 1:

The product design is not compatible with the local gas

group.

▶

Do not start up the product.

▶

Contact customer service.

Result 2:

The product design is compatible with the local gas

group.

▶

Check the gas connection pressure/gas flow pres-

sure. (

▶

Check the CO

₂

content. (

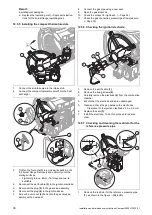

9.6.2

Checking the air/flue pipe/flue gas

recirculation

1.

Check the flue gas installation is intact in accordance

with the latest gas safe technical bulletin and informa-

tion supplied in the installation instructions.

2.

For extended flue gas installations check for flue gas

recirculation using the air analysis point.

3.

Use a flue gas analyser.

4.

If you discover unusual levels of CO or CO

2

in the

supply air, search for the leak in the flue system or for

signs of flue gas recirculation.

5.

Eliminate the damage properly.

6.

Check again whether the supply air contains any un-

usual levels of CO or CO

2

.

7.

If you cannot eliminate the damage, do not start up the

product.